Sustainable closure sealing and labelling of fruit and vegetable trays

18/08/2022

New solutions from MULTIVAC for environmentally-friendly labelling

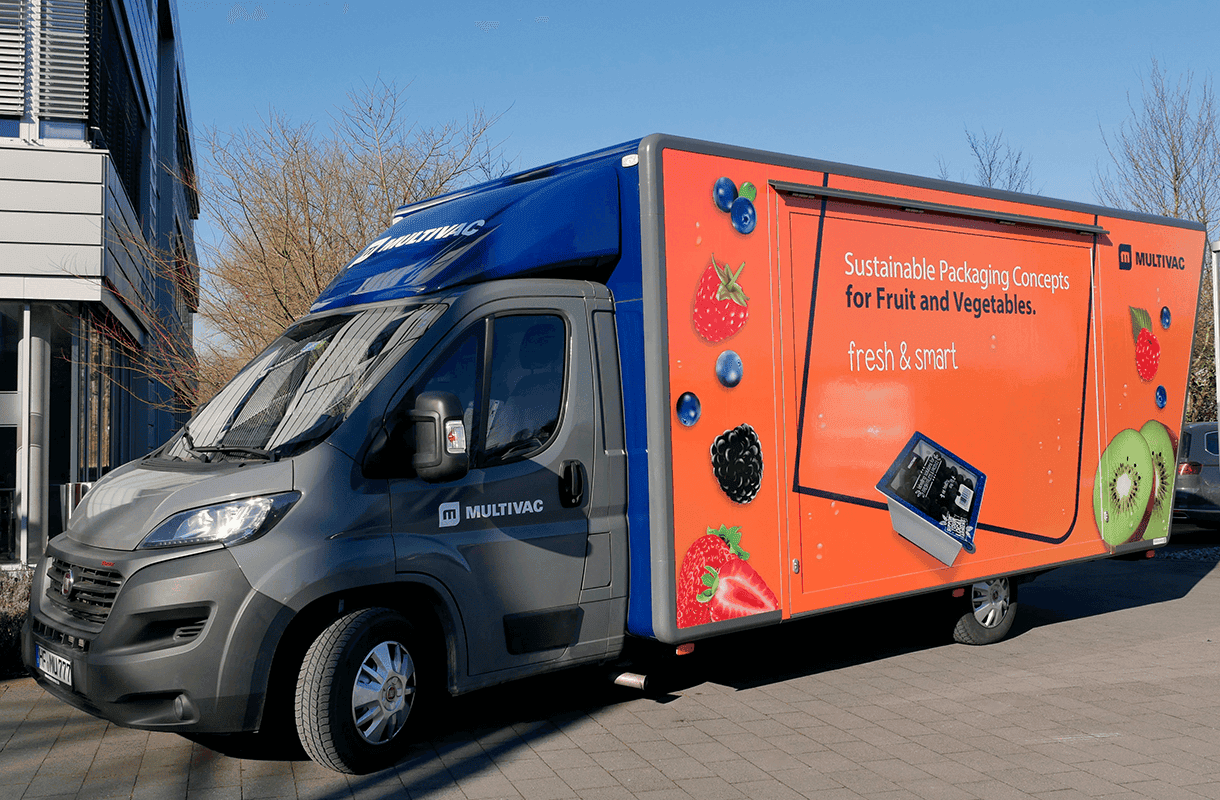

Wolfertschwenden, 18 August 2022 - A new trend is evident, particularly with natural products such as fruit and vegetables: Packaging and labelling has to be very sustainable nowadays - and also especially secure. Rethinking is the new creed. In addition to its groundbreaking concept of Full Wrap, MULTIVAC Marking & Inspection now offers two more high-quality and sustainable labelling solutions for fresh produce trays - Top Wrap and Top Close.

In Germany around 60 percent of fresh fruit and vegetables is sold pre-packed in retail outlets. Two thirds of the packs are based on plastic, and the remaining one third on cardboard or other paper fibre materials. Plastic packs in particular are often viewed critically by environmentally-conscious consumers - but without justification. Because packs protect food along the entire process chain. They preserve the freshness and appetising appearance of the product. They extend the shelf life and therefore make a major contribution to preventing food waste due to premature spoilage. And last but not least, their CO2 balance is also very impressive. The latest studies show, that the ecological footprint of a processed food product is generally up to 30 times higher than the footprint of its packaging. Within the food sector in Germany, the proportion taken up by the packaging is just one to three percent.

MULTIVAC recognized the signs of the times at an early stage

In spite of these figures, every gram of packaging material saved helps the environment. As does every conventional packaging material, which is replaced with a recyclable and more material-efficient substitute. MULTIVAC is a solution provider, which has been working intensively for years on optimising the sustainability and efficiency of packaging and labelling concepts. The labelling specialists from the Westphalian town of Enger have already set the benchmark in the sector with their full wrap labelling. Now follows the next stroke: Top Wrap and Top Close appear just in time for FachPack 2022 - two more powerful concepts for the closure sealing and labelling of fruit and vegetable trays.

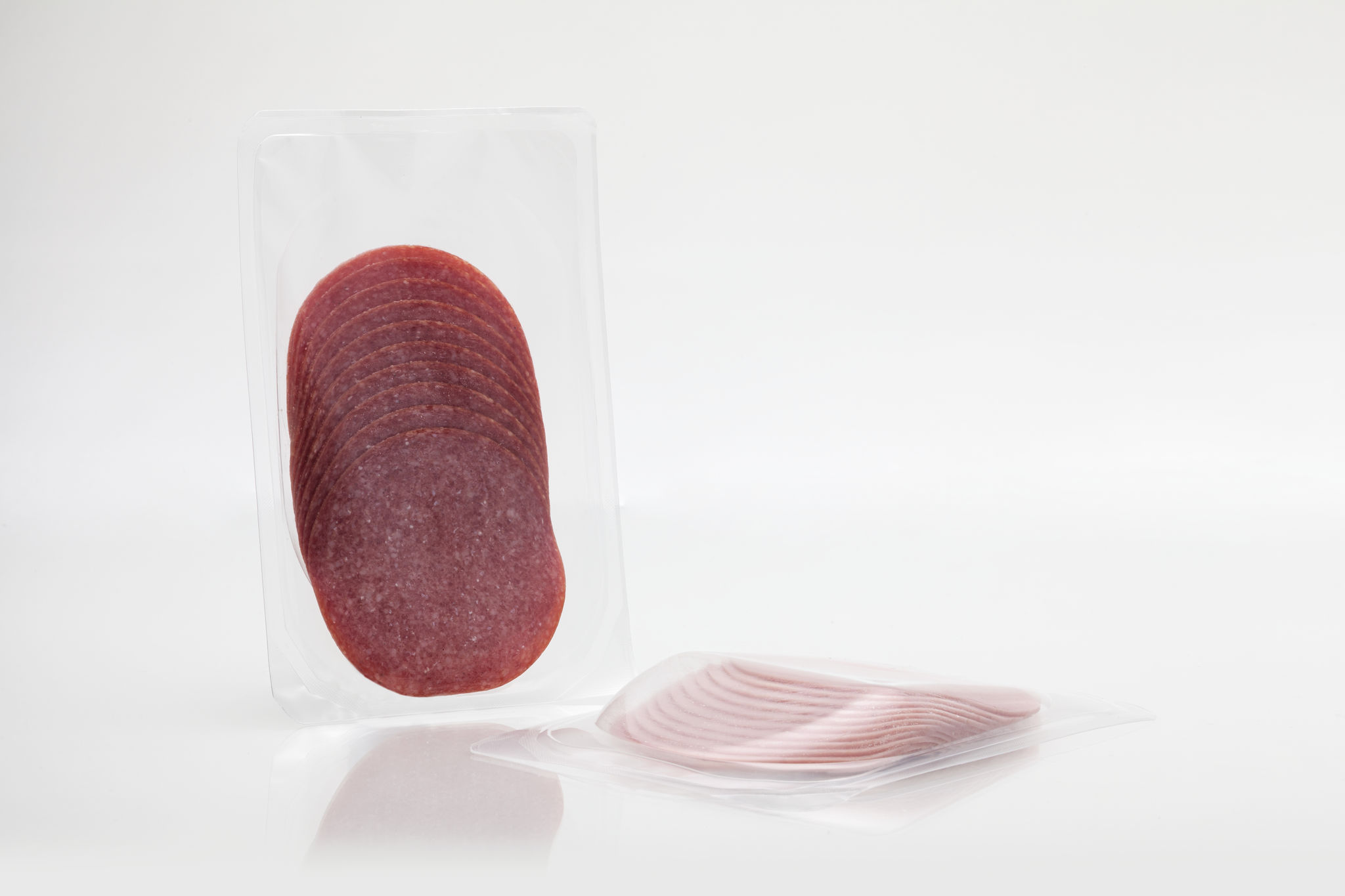

Whereas Top Wrap involves applying a label to the top and both sides of the tray, Top Close seals the tray closed just with a label from above. Both concepts are the ideal choice for all fresh products, which do not have to be packed under modified atmosphere or airtight in a vacuum. This means that a label can be used to simply seal the tray closed and label it attractively at the same time. Both labelling solutions have one thing in common: They provide a strong purchasing incentive thanks to their attractive label and recyclable pack.

The self-adhesive labels on a backing material not only offer a large area for customer information and marketing purposes, they also open up a wide range of possibilities for product presentation in terms of material thickness and label shape. It is possible for example to have cut-outs in the label, as well as adhesive-free zones, so that contact with the product is prevented. Perforations serve as opening aids and make the handling of the packs easy for the consumer.

With Top Wrap ...

The label makes sure, that the content can not fall out of the tray or be removed by the customer. But in contrast however to full wrap labelling, the label is only applied to the top and two sides, and not around the complete pack. This saves material and ultimately resources, and the label achieves its purpose in equal measure.

“Thanks to a combination of cardboard trays and standard self-adhesive labels made of paper or renewable materials, this produces a pack that can be sorted perfectly into its separate components for recycling,” emphasizes Michael Reffke, Product Manager for Labelling Technology at MULTIVAC Marking & Inspection in Enger.

In addition to this, it is also possible with Top Wrap to use film labels made of polypropylene. Polypropylene labels offer the great benefit of providing the optimum view of the product thanks to a transparent window on the top of the tray. Since the backing material is not peeled off in this area, the content of the tray is protected against contact with the label adhesive. And as Michael Reffke says, “The proportion of plastic in such a pack is under 10 % depending on the label material used. The label can also be easily removed, making it simple for the consumer to separate the materials into the different recycling channels.”

With Top Close ...

Plastic or cardboard trays with a wide flange or even round trays can be sealed closed simply and securely on the top and labelled at the same time. The label only adheres to the flanges of the tray. Thanks to an adhesive-free zone or retention of the backing material in the middle of the label, the product does not come into contact with the adhesive. Transparent labels also allow an optimum view of the product, while ventilation holes ensure that there is air circulation. The label can also be printed on the labeller itself with a best-before date for example, and it is even possible to inspect the print on the label.

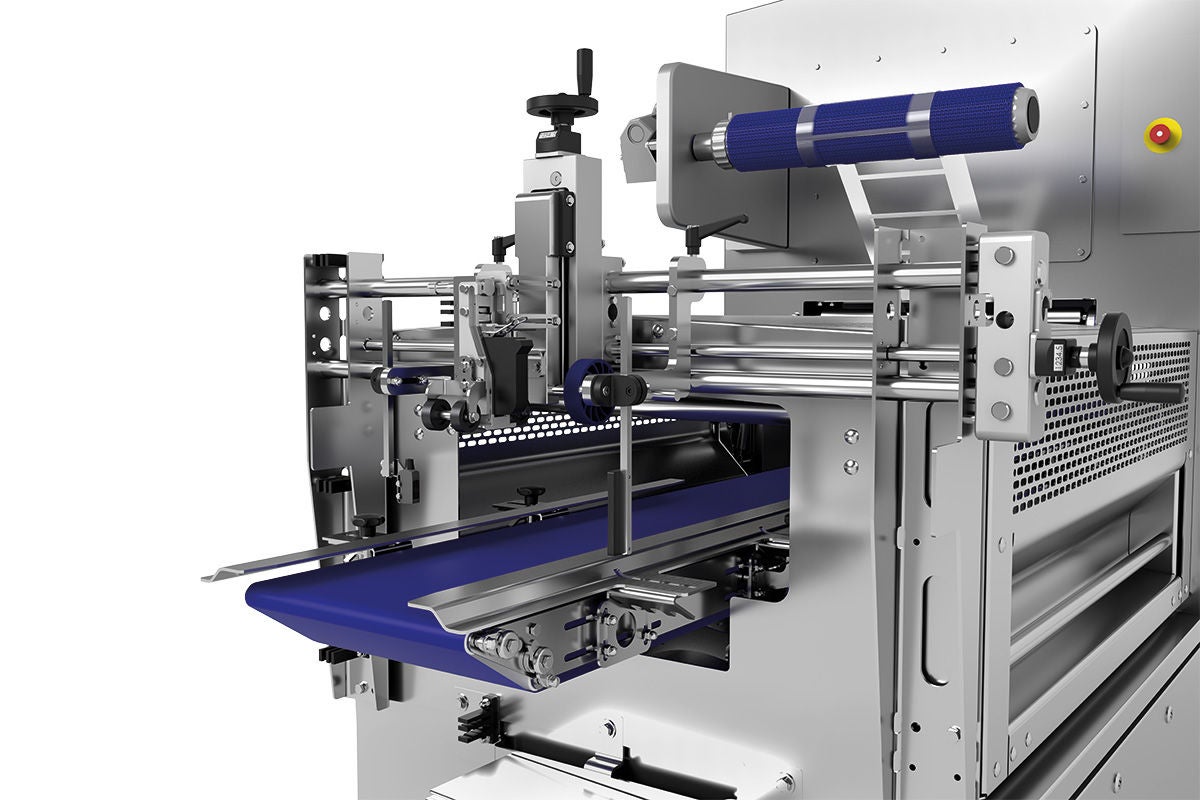

With an output of up to 200 products per minute, a labeller with Top Close has a particularly high output. The trays are automatically labelled on the run, and they are either fed in manually or transferred automatically from an upstream module. When compared with time-consuming, manual packaging solutions, this provides tangible cost savings and a very efficient process.

MULTIVAC conveyor belt labellers - high-output and very flexible

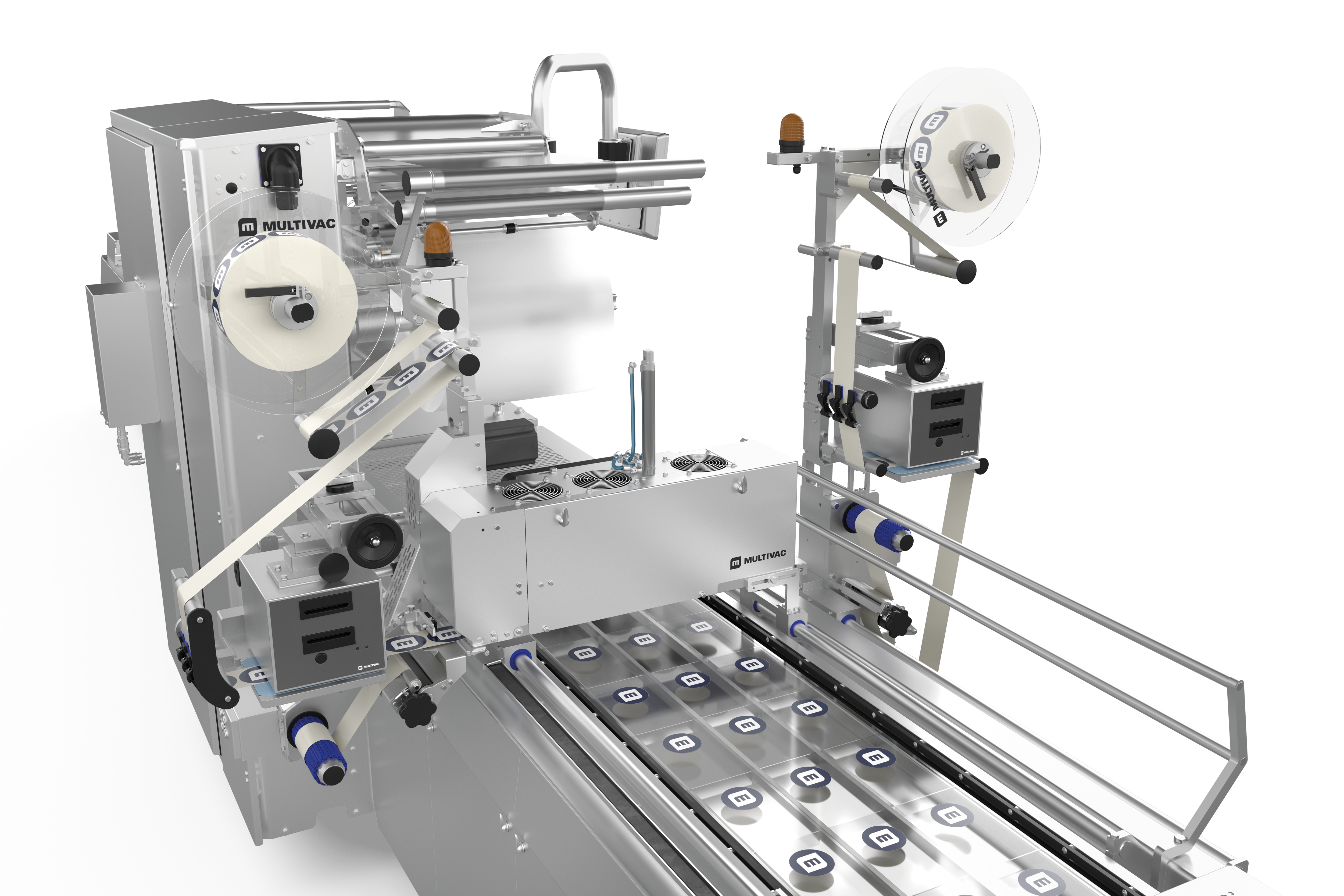

MULTIVAC's high-output conveyor belt labellers, such as the L 310 FW or the L 312 FW with weigh price marking, which was presented for the first time at Anuga FoodTec 2022, offer a wide range of different labelling solutions depending on the type and content of the tray as well as the packaging materials used. The models can be integrated seamlessly into existing lines, or they can be used as a stand-alone solution with manual product infeed.

Since MULTIVAC Marking & Inspection is currently celebrating its 50th anniversary, an attractive birthday bonus is on offer for all customers, who decide on the purchase of a conveyor belt labeller before the end of 2022.

Ultime notizie

2327146963

2327146963

MULTIVAC Packaging Solutions at ACHEMA 2024

MULTIVAC Packaging Solutions at ACHEMA 2024

ANUGA FoodTec Presentation Event Highlights

ANUGA FoodTec Presentation Event Highlights

MULTIVAC Bakery Equipment Storefront Exterior

MULTIVAC Bakery Equipment Storefront Exterior

Pet Food Packaging Solutions by MULTIVAC

Pet Food Packaging Solutions by MULTIVAC

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Opening Ceremony Event

MULTIVAC Opening Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

MULTIVAC PDF

MULTIVAC PDF

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Factory Opening Ceremony Event

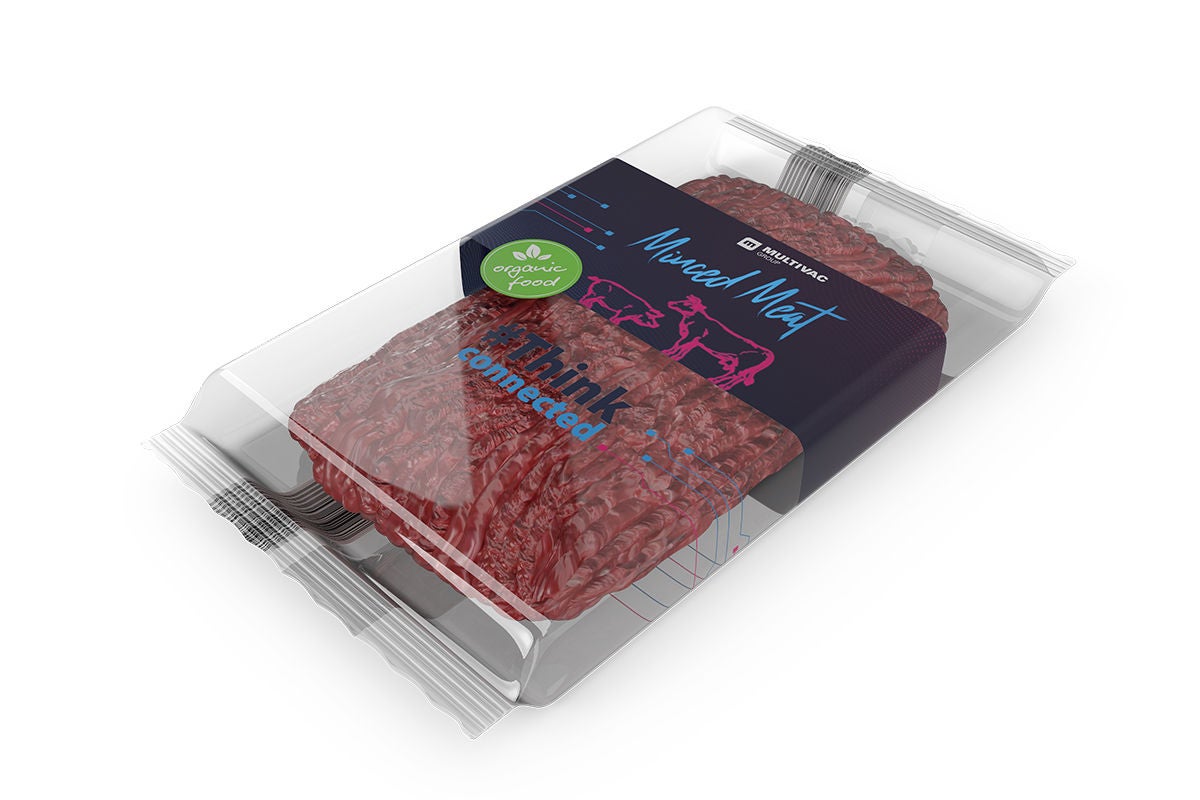

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC Sustainable Packaging for Fresh Produce

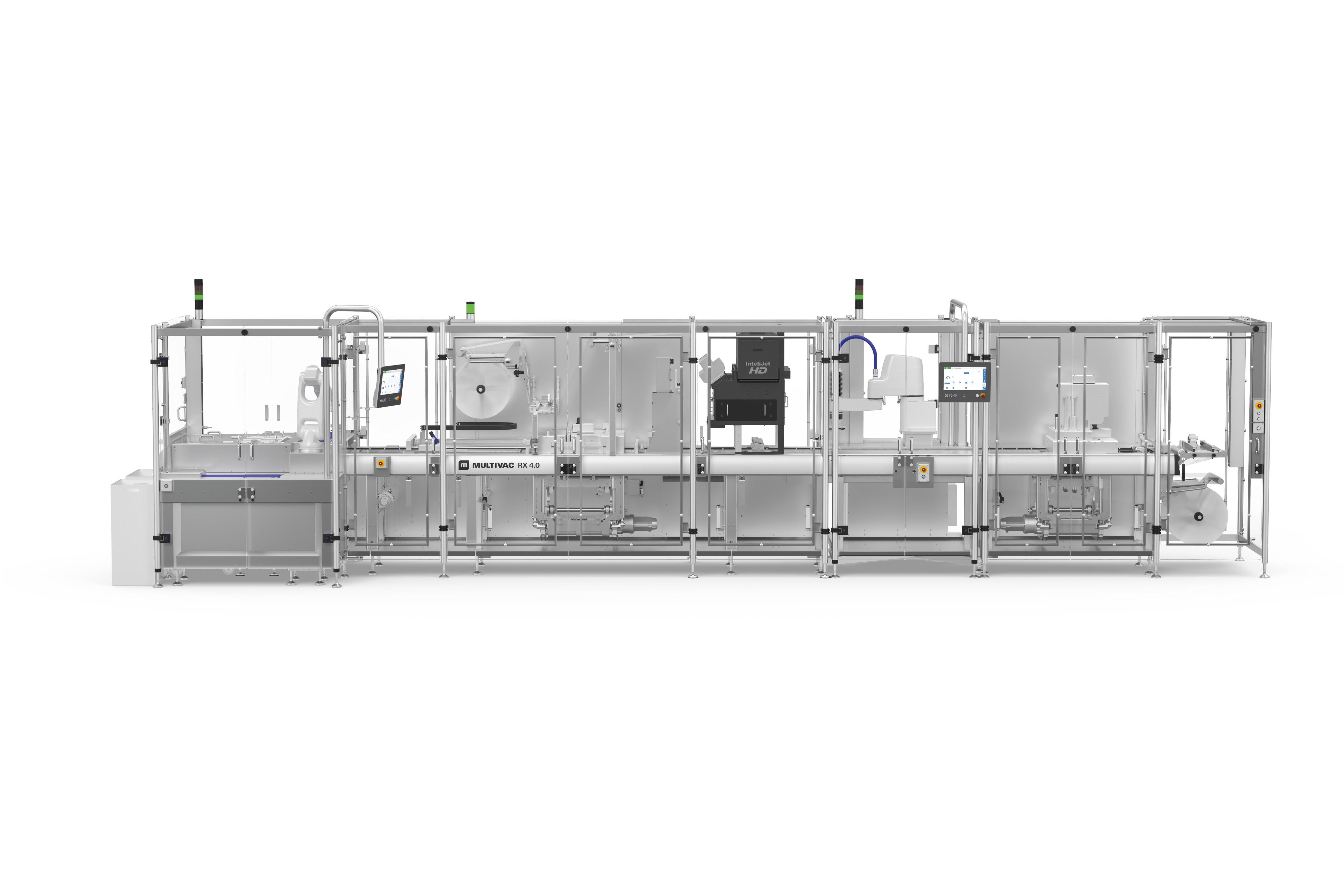

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC Website Displayed on Tablet Screen

MULTIVAC Website Displayed on Tablet Screen

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

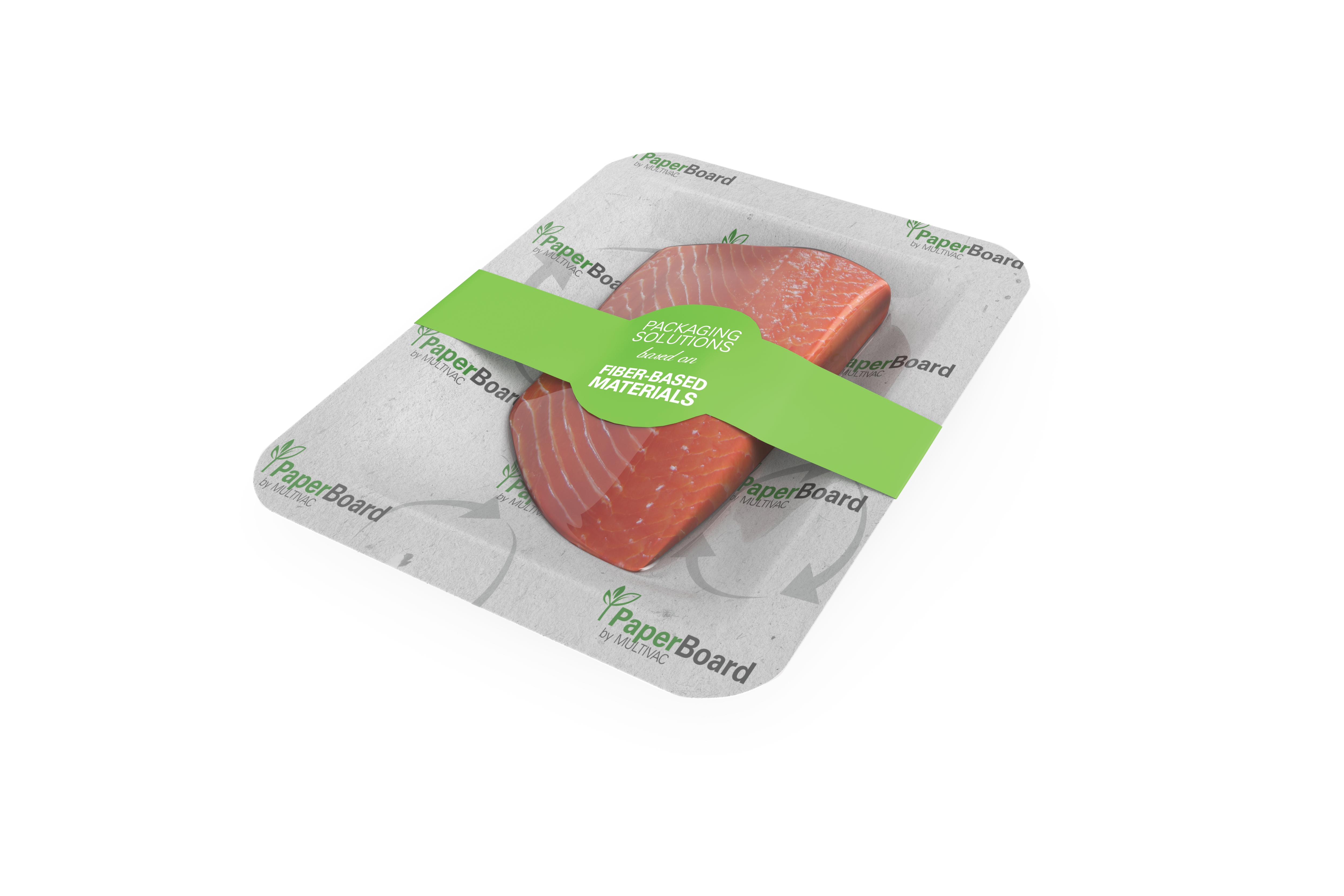

Seafood Packaging Solutions by MULTIVAC

Seafood Packaging Solutions by MULTIVAC

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

MULTIVAC Sustainable Packaging Solutions

MULTIVAC Sustainable Packaging Solutions

Vegetable Soup Bowl on Wooden Table

Vegetable Soup Bowl on Wooden Table

MULTIVAC Future Proteins Conference Banner

MULTIVAC Future Proteins Conference Banner

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

Business Professional Portrait with Blurred Face

Business Professional Portrait with Blurred Face

Businessman in Formal Suit Portrait

Businessman in Formal Suit Portrait

Industrial Machinery Setup MULTIVAC Factory Overview

Industrial Machinery Setup MULTIVAC Factory Overview

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Food Packaging Machine Display

MULTIVAC Food Packaging Machine Display

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine High-Speed Efficiency

MULTIVAC Packaging Machine High-Speed Efficiency

Community Event in Large Tent Gathering

Community Event in Large Tent Gathering

MULTIVAC Anniversary Celebration Image

MULTIVAC Anniversary Celebration Image

Fleischer-Handwerk Award Ceremony Event Photo

Fleischer-Handwerk Award Ceremony Event Photo

MULTIVAC Trade Show Presentation

MULTIVAC Trade Show Presentation

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

Tanja Böck

Public Relations Manager

Tel: +49 8334 601-0

Mail: press@multivac-group.com