Skift placering

Nuværende placering

By Dr Marius Grathwohl, Vice President Digital Products and Transformation at MULTIVAC, supplier of processing and packaging solutions

With industry becoming increasingly digitalised, new opportunities are being opened up by digital services to optimise the efficiency and sustainability of production lines. By using artificial intelligence (AI), IoT solutions and "big data", machines are able to not only work more productively, but also offer manufacturers the opportunity to become more proactive. But where is the best starting point for manufacturing companies, if they want to use Smart Services for their production, and what benefits can they expect from these solutions in these cost-sensitive times?

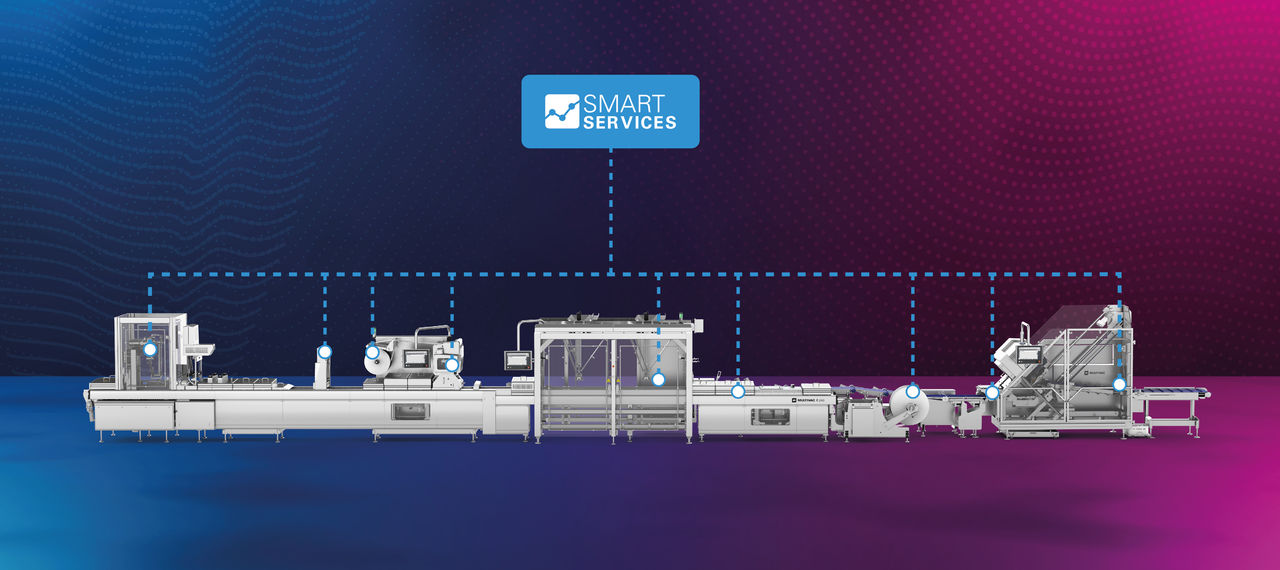

Digital services, such as for example MULTIVAC Smart Services, are intelligent resources which, by analysing "smart data" and using machine networking, are precisely tailored to the individual needs of a manufacturing company. By automating centralised processes, it is possible to increase machine availability and elevate the entire production performance. For example, machines with integrated IoT sensors can be monitored continuously, so that any anomalies, such as discrepancies in operating pressure or temperature, can be detected early and rectified quickly in a targeted way. The requirement for personnel is also reduced at the same time, since routine tasks such as status checks or simple calibration can be undertaken by "smart systems".

Smart Services also make it possible to adapt production to changing requirements. This ease of scaling-up can be seen particularly clearly, if production capacity has to be expanded rapidly. By using an integrated Smart Services panel for networking, it is possible to link new machines into the existing infrastructure, without having to make time-consuming adaptations to the system. A food manufacturer can for example integrate an additional packing station at short notice into his packaging line, so that he can react quickly to a rise in demand.

Data collected from sensors on all the company's machines provides a solid basis for accurate production planning: Key performance indicators and daily production targets can be viewed in real time, while operating data such as machine output and pack quality can also be continuously analysed. If any discrepancies arise, for example a sudden increase in rejected products, counter-measures can be introduced quickly. Operation that is optimised in this way means lower energy consumption and less use of resources.

By integrating Smart Services into everyday working, it is also possible to make it easier for new or unskilled employees to operate the machines. Digital platforms and intuitive user interfaces enable operators to develop a better understanding of the operation of machines and lines. Access to real-time data about the machine status and performance promotes greater confidence and safety, when dealing with technology. Even new employees can quickly make decisions on their own, such as for example about the planning of maintenance work.

Preventive maintenance, also known as "predictive maintenance", is one of the most important strengths of Smart Services. The objective is to identify and eliminate potential problems on machines, before it gets to costly breakdowns or emergency repairs. To do this, "smart systems" continuously analyse the machine data in order to detect signs of wear, overload or other risks at an early stage. This data-based support helps to not only ensure, that the machine operates more efficiently and cost-effectively, but also to plan maintenance work more precisely.

This means that, thanks to Smart Services, production teams benefit from customer service that is more individual, faster and higher-quality. Thanks to the machine's connection to the cloud, the machine manufacturer's service technicians are constantly "up to speed" on the pending maintenance work, and they can warn their customers in advance about any machine breakdowns that may be threatening. In addition to preventing emergencies, such "smart systems" also reduce the work involved in maintenance planning. The necessary maintenance stages, which previously had to be looked up in instruction manuals, can today be provided digitally and automatically, and they can even be carried out with the virtual support of a remote service technician if required. Not only is time saved, but the quality of the maintenance is increased.

Where can companies make a start, when introducing Smart Services into their production lines? The introduction requires comprehensive preparation in all aspects of technology, security and organisation. Since Smart Services complement the existing "system landscape" instead of replacing it, they represent a simple digitalisation exercise, even for companies with established processes. Companies need to change relatively little in their data management in order to be able to use the benefits of Smart Services. When embarking on the introduction, it is recommended that one starts with a line, where a breakdown would have significant effects on the entire production. Only in this way can the benefits of Smart Services unfold in full from the beginning.

Connection to the cloud is a central requirement for the use of Smart Services. Depending on the particular application, companies can opt for edge computing, if low-latency evaluation or pre-processing of the data is necessary, or they can process the collected data in the cloud, for example if the analysis is more extensive, or if real-time support by the machine manufacturer is required. By implementing strict access controls and encryption, it is possible to make sure that only authorised parties can gain access to this data.

But the potential danger of cyber attacks also increases, when machines and production systems are networked in this way. Companies should take these threats very seriously and regularly install security updates and patches provided by machine manufacturers. In order to ensure this, machines should always be kept online, and not isolated offline for reasons of perceived protection – only in this way can security gaps be closed permanently. Companies should also keep their production network separate from their main network, as well as connecting the machines to the cloud separately from each other. This provides fewer opportunities for large-scale cyber attacks.

Overall there is a need for strategic planning, when introducing Smart Services to a company. Successful introduction requires a clear vision, which should be laid down and supported by the company management, particularly the CTO. In addition to the Procurement and IT Security departments, it is also essential to involve the Heads of the Technical departments, the line supervisors and operators, as well as the production managers, in the critical decision-making process about Smart Services.

An open and interoperable ecosystem is a central challenge in the introduction of Smart Services. Companies must be in a position to connect various systems and machines seamlessly with each other. To do this, they must create a digital ecosystem, which operates across all machine manufacturers and offers standardised communication protocols.

One particularly forward-looking solution in this context is the so-called "asset administration shell", which serves as a central directory for all machine-related information. It references the following information for example throughout the entire life cycle of a machine:

The asset administration shell enables a high degree of standardisation to be achieved, since it makes it easier to integrate machines from both the manufacturers themselves and their third-party suppliers. It can also function as a central building block for providing a digital twin of the machine, since it makes the data for this available at a central location. Thanks to interfaces with different systems, the asset administration shell can also support the integration of automation and AI applications.

Since consumption data can also be embedded in the asset administration shell, it is possible to monitor the environmental performance of the machine in real time. The relevance of this is increasing as a consequence of regulatory developments, such as the EU Eco Design Directive. One of its demands is the provision of a digital "product passport", which is intended to include information about the environmental effects of a product over its entire life cycle.

The future of the manufacturing sector lies in establishing open digital ecosystems, in which connectivity forms the basis for innovation and growth. There are also political questions here: A clear defining of Industry 4.0, as well as targeted promotional programs and support for companies in implementing the technology, could significantly strengthen Germany's international competitiveness. In 2019 MULTIVAC was one of the founder members of the Open Industry 4.0 Alliance, and in this context it has since designed open ecosystems with other companies. Examples from other European countries such as Italy show, that by fostering those companies, which implement Smart-Services, this can have a crucial impact on digitalisation. Germany should follow this example as well. When correctly implemented and supported, Smart Services have the potential to be a critical lever for long-term competitiveness and sustainability in all aspects of production.

15.09.2025