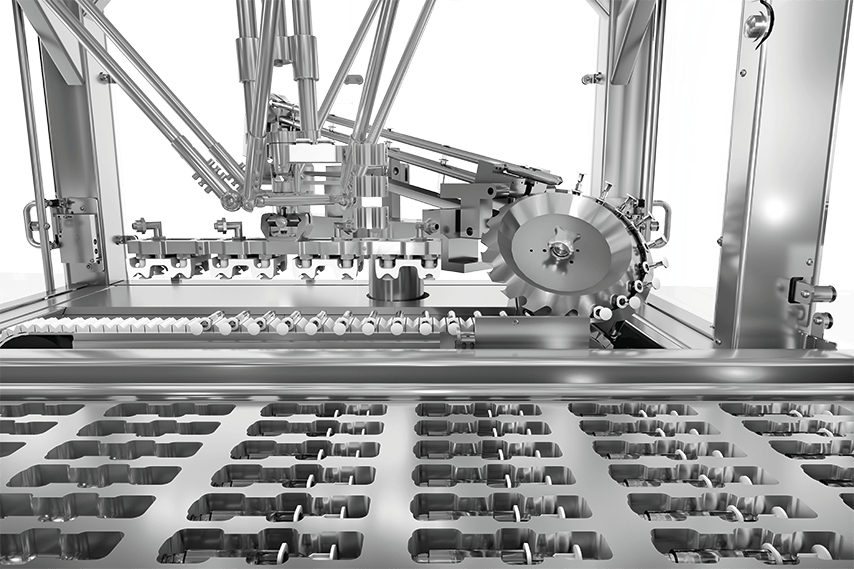

The system is suitable for pre-filled glass and plastic syringes with or without hollow needles. With a handling speed of up to 300 syringes per minute, the system ensures syringes are fed to the thermoforming packaging machine in a controlled and reliable process. The system is designed for syringes with a diameter of 6.5 to 25 mm and a length of 70 to 150 mm.

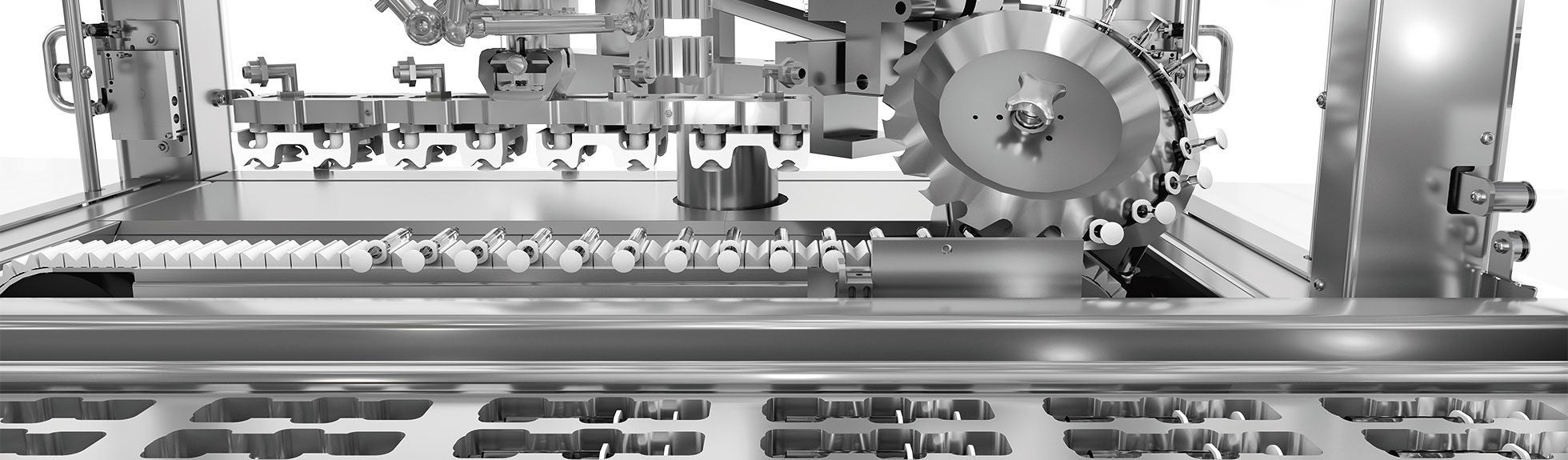

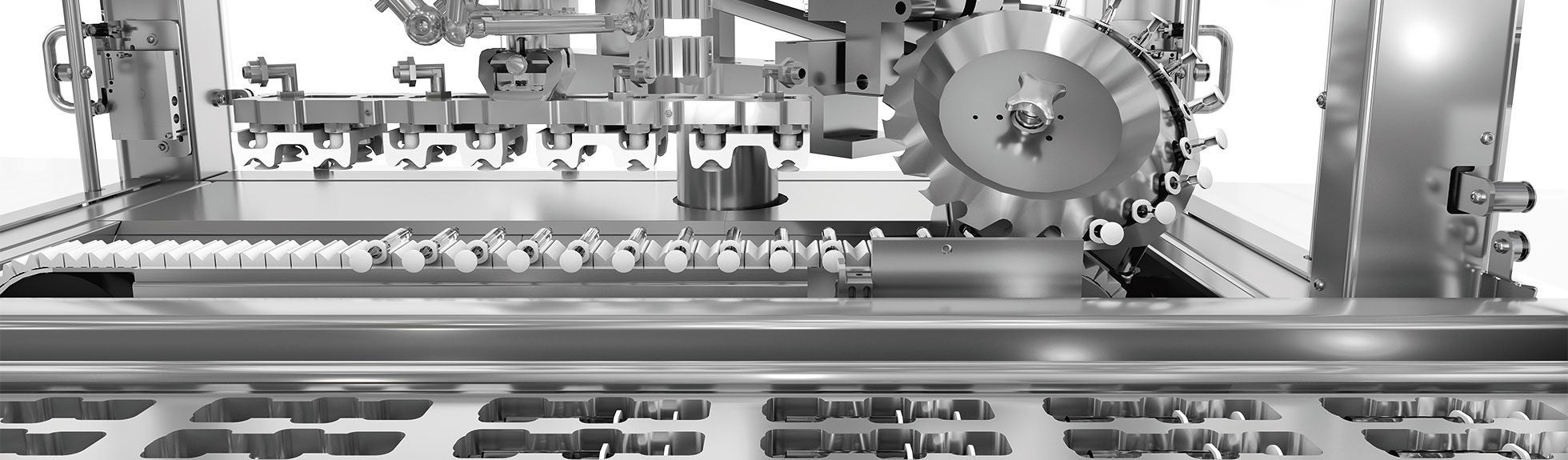

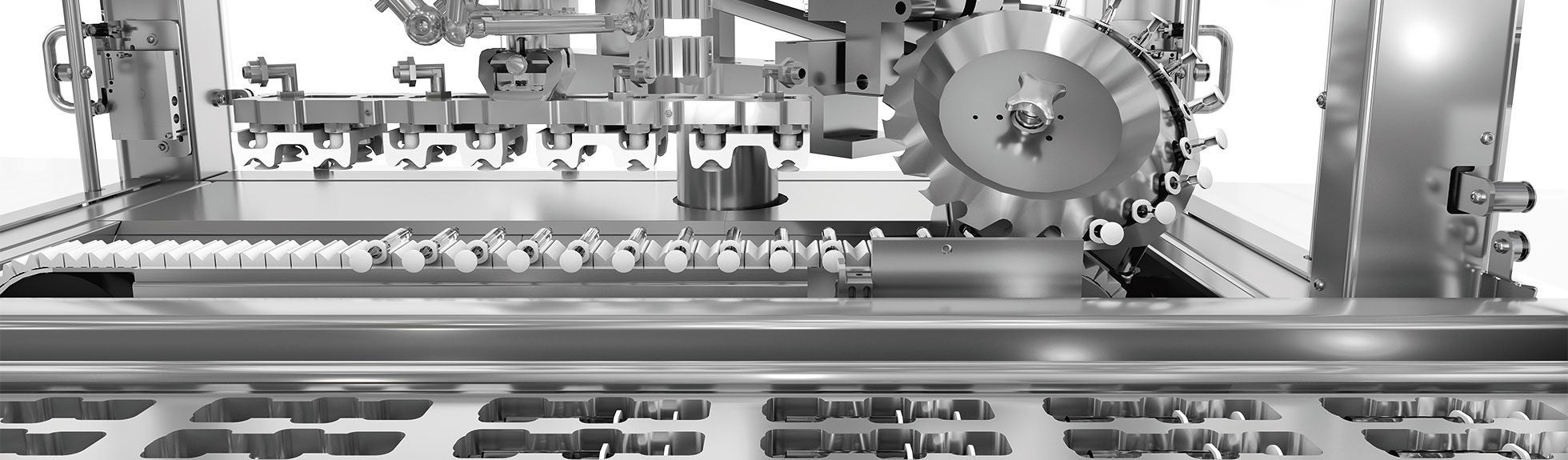

The delicate products are held hanging vertically by their flanges as they are transported to the actual loading system by means of a product infeed conveyor. The syringes arrive on transport rails at a star wheel, where they are separated and orientated. The vertical syringes are then aligned horizontally. The star wheel transfers the syringes to a servo-driven trapezoidal belt. There they are taken up by a pick-and-place robot and deposited in the formed pack cavities of the thermoforming packaging machine.

The infeed system guarantees a controlled infeed process and offers a high degree of flexibility with the option of easy and fast conversion between various syringe and carrier formats. The star wheel and trapezoidal belt can be replaced in a short time without the use of tools - this reduces downtimes, thus increasing the efficiency of the entire system. Control is user-friendly and safe via the HMI of the thermoforming packaging machine.

10.10.2017