Skift placering

Nuværende placering

The Swiss company skilfully combines traditional hand-crafted methods with state-of-the-art production and packaging technology. When it comes to labelling, the dry meat producer is constantly developing – since March 2019 the trays, in which the innovative snack products are packed, have been labelled automatically and therefore highly efficiently on a full wrap labeller from MULTIVAC.

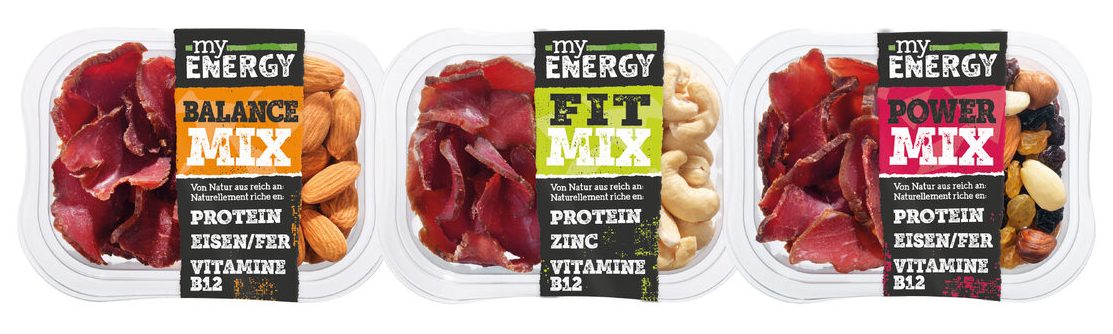

The "my ENERGY" products are healthy, protein-rich snacks for eating on the go. In addition to spicy beef sticks packed in handy film pouches, Albert Spiess also offers "filling power packs" for snacks between meals, and these consist of spicy dry meat and different nut mixes - from sweet nutty to salty spicy. The different product types are packed in rectangular trays, which are divided into two compartments - one cavity for beef chips and one for the corresponding nut mix. Each individual product variant has its own label colour.

No effort has been spared at Albert Spiess to highlight the attention-grabbing presentation of the packs at the point of sale. “The trays were inserted manually into high-quality cardboard sleeves. A base label with use-by date and price was then applied on a weigh-price labeller,” recalls Marketing Manager, Erwin Brägger.

This type of pack design and labelling was intended to highlight the company's claim to high quality and finest hand-crafted processing, as well as underlining the close relationship with nature through the use of paper fibre-based materials. Sustainability lies at the heart of the company, which was founded in 1906 in the town of Schiers in the canton of Prättigau, and which has been part of ORIOR AG since 2008. “Our "Bündnerfleisch" meat specialities stand for tradition and closeness to nature - we see ourselves as guardians of an ancient heritage. But at the same time we are also aware that, as one of the leading suppliers in this market, we must push forward with developments and use new technological opportunities sensibly,” says Erwin Brägger, summarising the company's philosophy.

It is for this reason that they looked for new labelling opportunities. The manual application of the cardboard sleeves was very time-consuming. The changeover to a largely automated process was intended to increase the efficiency and cost-effectiveness, without reducing the appeal of the well established packs in the market.

At the same time however, the special banderole form had to be retained. This offers sufficient space in a wide area on the side of the tray to provide the required nutritional information. The banderole tapers on the top of the tray. As with the previously used cardboard sleeve, the side edges have a typically frayed structure, which is reminiscent of torn handmade paper.

A L 310 conveyor belt labeller from MULTIVAC Marking & Inspection has been in use since March 2019. This high-performance model is designed at Albert Spiess to be a stand-alone solution, onto which the packs are placed manually and then discharged downstream on a transport conveyor. The labeller is controlled via the HMI 2.0 control terminal.

The L 310 applies the 430 mm wide label automatically over all four sides of the pack with maximum positioning accuracy. Since the self-adhesive labels are stabilised by the backing material, it is possible in principle to consider virtually all shapes. Even the torn edges of the label design for the snack packs can be accurately represented. As Erwin Brägger says: “This would not have been possible with linerless labels. Severing the labels from the endless linerless material would inevitably have produced a clearly defined and in our case undesirable edge.”

The labels themselves are obtained directly from MULTIVAC. All the relevant properties such as design shape, material characteristics, adhesive-free zones, and perforations are matched precisely to the specific application. Each of the different colours for the various product types was also retained.

In order to achieve a visual and tactile effect, which came as close as possible to the previous cardboard sleeve, a label material was chosen with a relatively high grammage of

130 g/m2 and a slightly rough, matt surface structure. In order to enhance this effect, the label did without an allover application of adhesive. Instead of this, there were defined, adhesive-free zones, which give the impression of a banderole that is loosely wrapped around the tray. Perforations at the top and bottom edges serve as an opening aid and also make it easier to wrap the label around the pack.

A special challenge turned out to be the distinctive design. The underside of the pack is hollow due to the division of the tray into one cavity for beef chips and one for the corresponding nut mix. “The label had to be adhered over both compartments and bridge this hollow,” explains the Marketing Manager. The packaging experts from MULTIVAC were once again called upon to find a solution. It was a question of finding a suitable adhesive with sufficiently good adhesion to enable the label to be applied automatically, without causing any undesirable creases to be formed.

Everyone at Albert Spiess has been highly delighted with the new labelling system from the start. “With the L 310 we can label up to 120 packs per minute. The whole packaging process has massively simplified and accelerated everything for us,” says Erwin Brägger, summarising the very positive experience with the labeller. The automated solution also ensures the consistently accurate application of labels – another benefit over the previous manual application.

It is also very pleasing, that the appeal of the packs and the positive brand image have not been diminished in any way. “This project has enabled us to remain true to our basic principles – we can continue to develop traditionally produced, first-class "Bündnerfleisch" meat specialities in an innovative product line, while labelling the packs very efficiently and cost-effectively on a high-performance full wrap labeller in the most attractive way possible on the market.”

05.11.2019