MUMI_Produktabbildung.indd

MUMI_Produktabbildung.indd

The L 320 series of labellers offers maximum flexibility when labelling products

New solution from MULTIVAC for labels on cylindrical or conical products and shaped bottles

18.02.2026

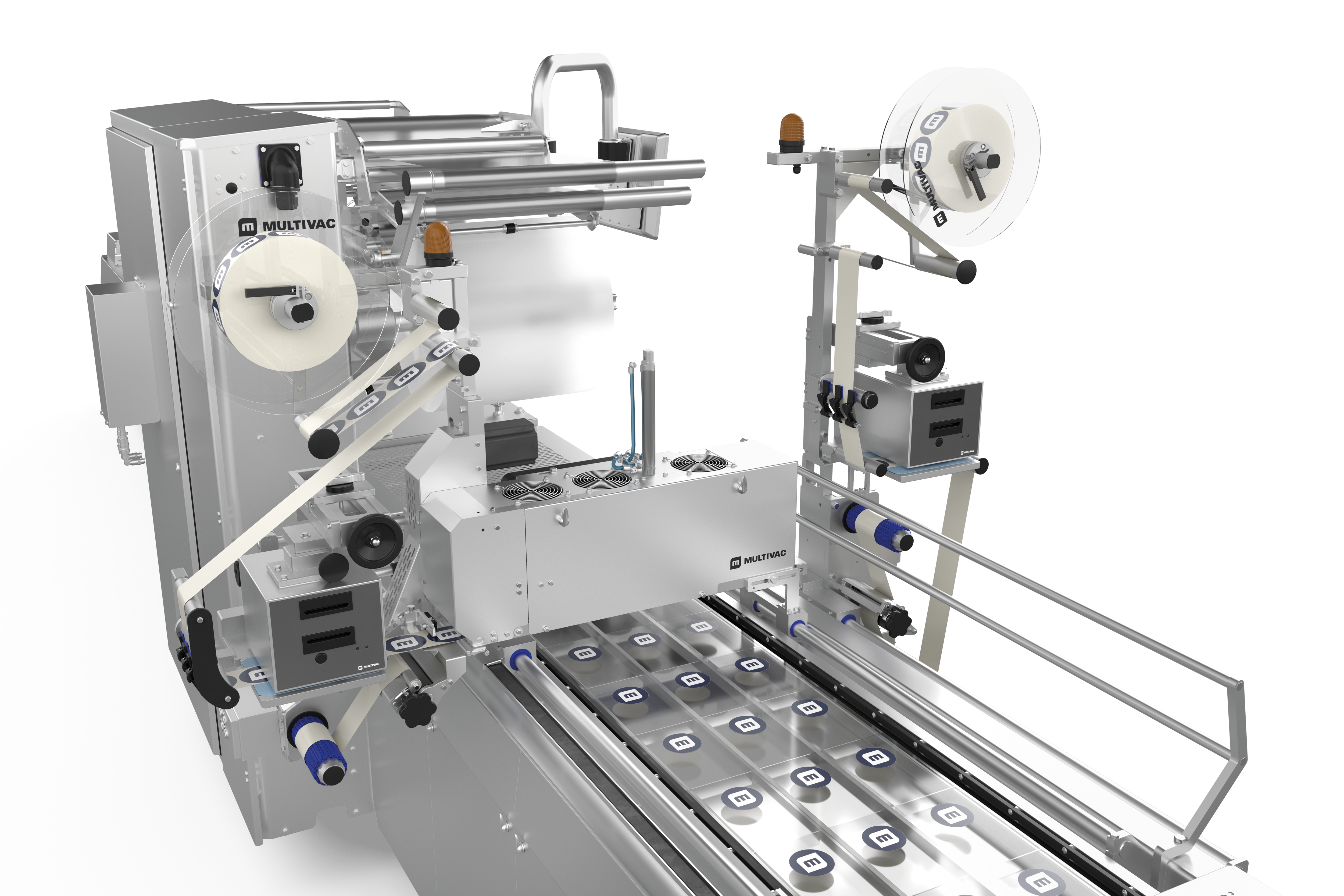

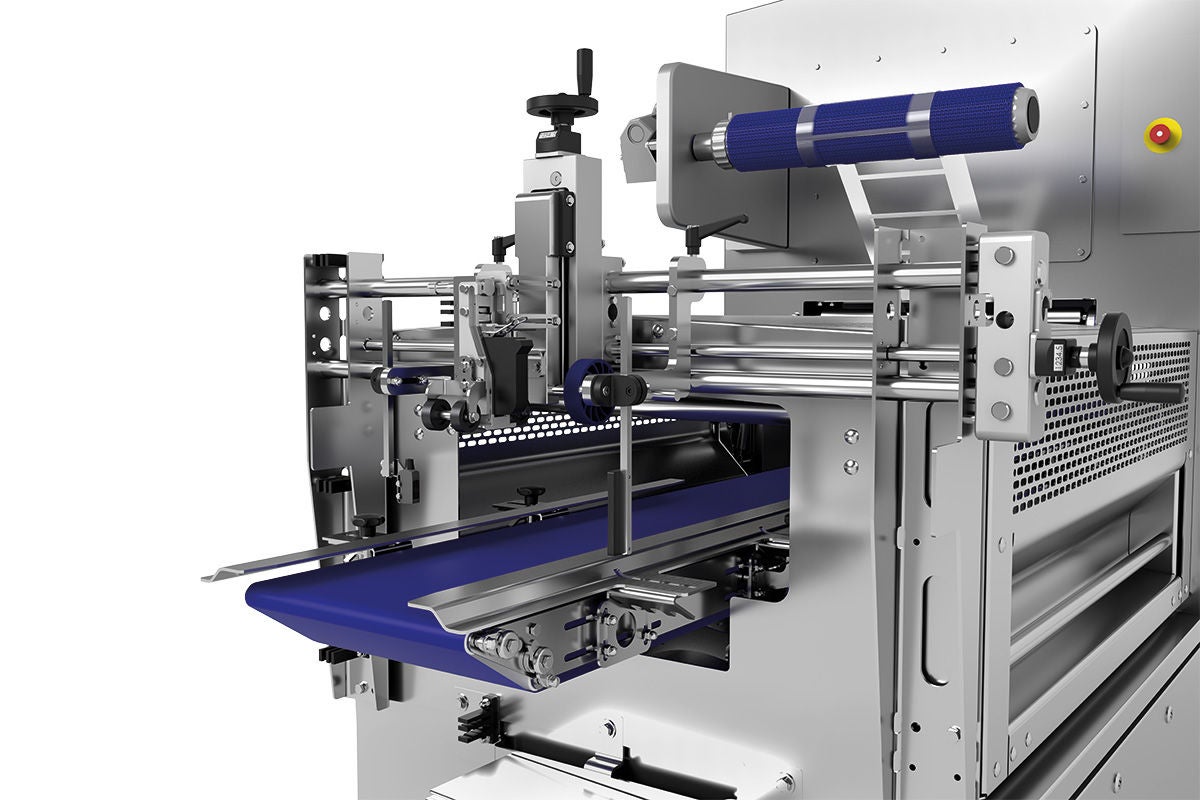

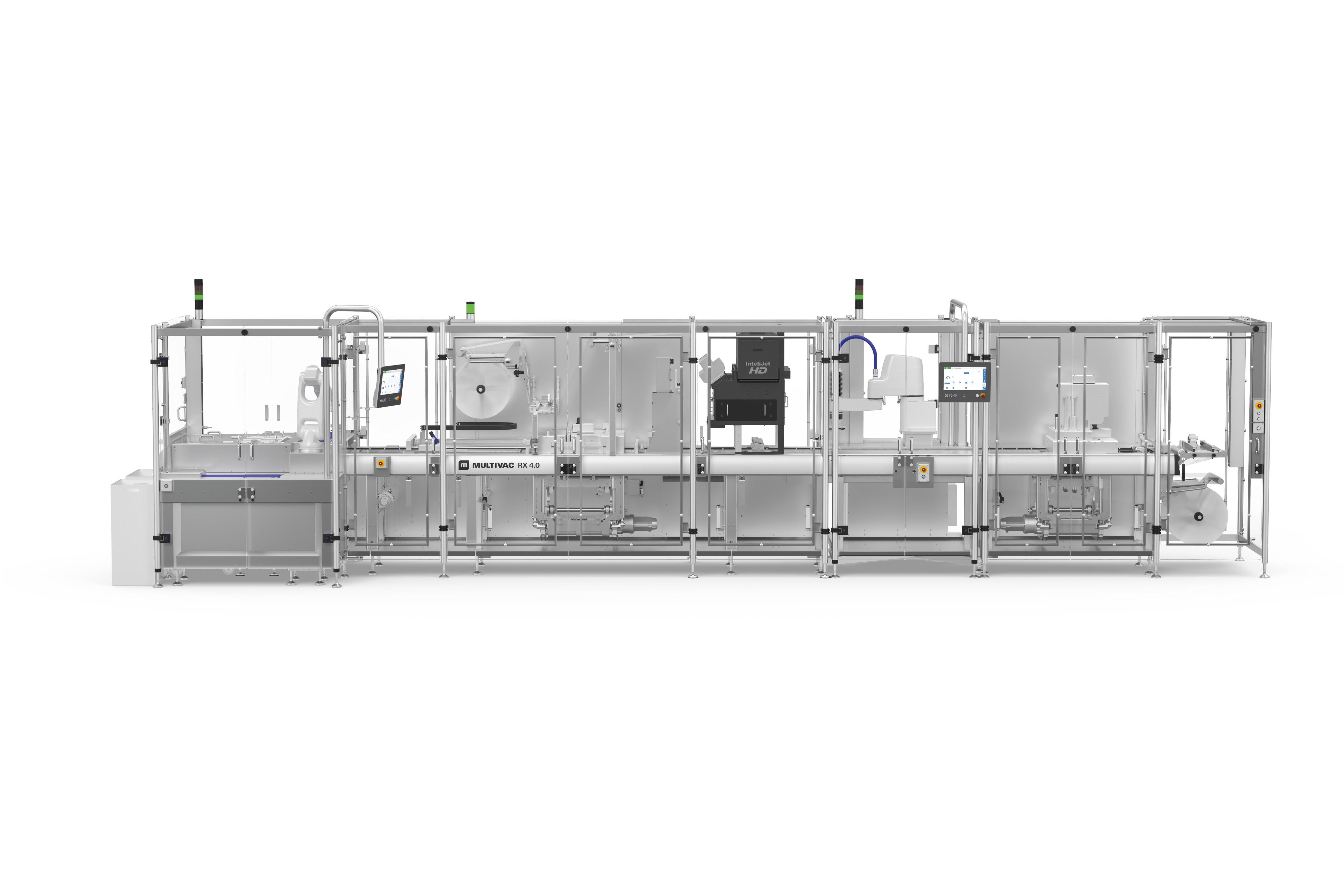

Wolfertschwenden, 18 February 2026 – With its new L 320 series of labellers, MULTIVAC is expanding its product portfolio with the addition of a high-performance solution, which offers companies maximum flexibility and precision in product labelling. The L 320 series can label cylindrical and conical products as well as shaped bottles, and it is very versatile in its configuration – whether wraparound, front/back or top labelling, and even applying sealing labels. MULTIVAC can therefore offer a flexible solution for challenging packaging tasks and exacting production environments.

The packs are first precisely converged and aligned on the transport conveyor, so that a highly accurate labelling result is achieved. A robust product guiding system ensures that the labels are applied exactly at the intended position. Depending on the particular requirement, several label dispensers can be integrated into the L 320, so that different labels can be applied in one operation. When combined with the "zero downtime" function, it is possible to achieve uninterrupted production. At the same time, the servo technology on the equipment ensures that maximum labelling accuracy is achieved. Various press-on devices, which are available as options, also provide consistently perfect label adhesion, even at high cycle rates.

Maximum efficiency in the smallest space

Thanks to their compact design, the L 320 labellers only require a small amount of space, and they can therefore be easily integrated into existing lines or accommodated in small business premises. Short conversion times, when changing products or label rolls, simplify production and make it highly flexible, particularly if batches are being changed frequently. The minimal servicing work required on the machine increases the availability of the equipment. The digital solutions provided by MULTIVAC Smart Services also enable the efficiency and performance of the labelling solution to be continually monitored and optimised.

Additional process reliability thanks to integrated printing and inspection technology

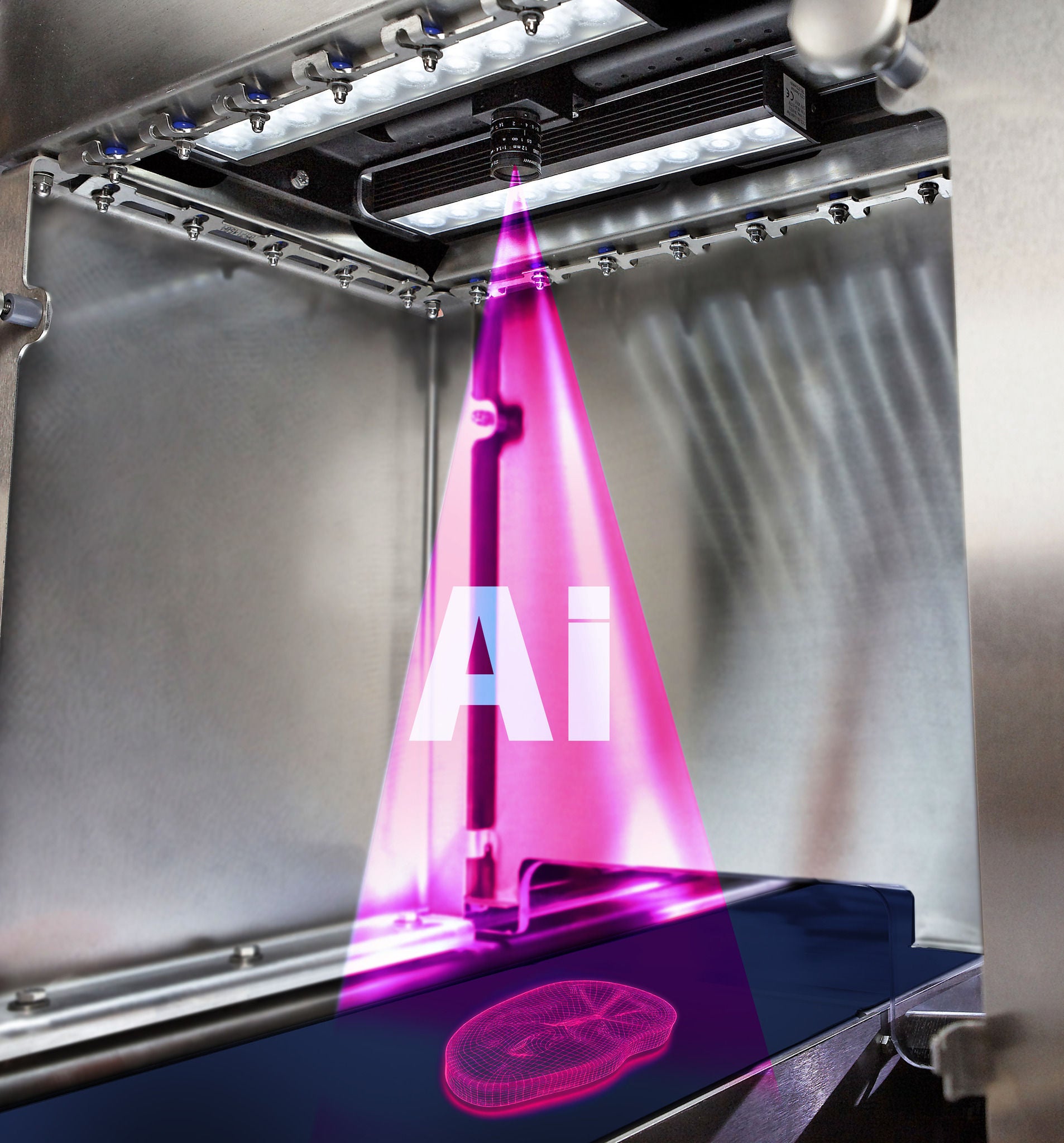

So that the maximum process reliability and product security are achieved, the L 320 series can be equipped with visual inspection systems. These carry out the comprehensive inspection of products, labels and print data – including the checking of label presence, barcodes and printed information, as well as pattern recognition and detection of label or product position. This means that both the correct labelling and the product quality are monitored continually, so that reject products can be automatically ejected from the line. Available as an option are integrated thermal transfer, thermal inkjet or continuous inkjet printers, which enable variable data to be printed onto the labels very flexibly during the labelling process. The L 320 series of labellers provides a technically sophisticated solution, which can be precisely adapted to different production requirements and integrated into many operating environments.

Press release

The L 320 series of labellers offers maximum flexibility when labelling products

- Size

- 144 KB

- Format

Image

New solution from MULTIVAC for labels on cylindrical or conical products and shaped bottles

- Size

- 485 KB

- Format

- jpeg

Current News

MUMI_Produktabbildung.indd

MUMI_Produktabbildung.indd

NASA Article images

NASA Article images

Jan 2026 Images

Jan 2026 Images

Jan 2026 Images

Jan 2026 Images

~ai-4ba7eba1-555f-4142-91a4-488abd4210a5_

~ai-4ba7eba1-555f-4142-91a4-488abd4210a5_

Clean Label Bread

Clean Label Bread

Mill Creek, WA USA - circa May 2022: View of a variety of beef jerky for sale inside a Town and Country grocery store.

Mill Creek, WA USA - circa May 2022: View of a variety of beef jerky for sale inside a Town and Country grocery store.

Directors Desk Header image

Directors Desk Header image

Power cover image

Power cover image

MULTIVAC Packaging Solutions at ACHEMA 2024

MULTIVAC Packaging Solutions at ACHEMA 2024

ANUGA FoodTec Presentation Event Highlights

ANUGA FoodTec Presentation Event Highlights

MULTIVAC Bakery Equipment Storefront Exterior

MULTIVAC Bakery Equipment Storefront Exterior

Pet Food Packaging Solutions by MULTIVAC

Pet Food Packaging Solutions by MULTIVAC

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Opening Ceremony Event

MULTIVAC Opening Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Factory Opening Ceremony Event

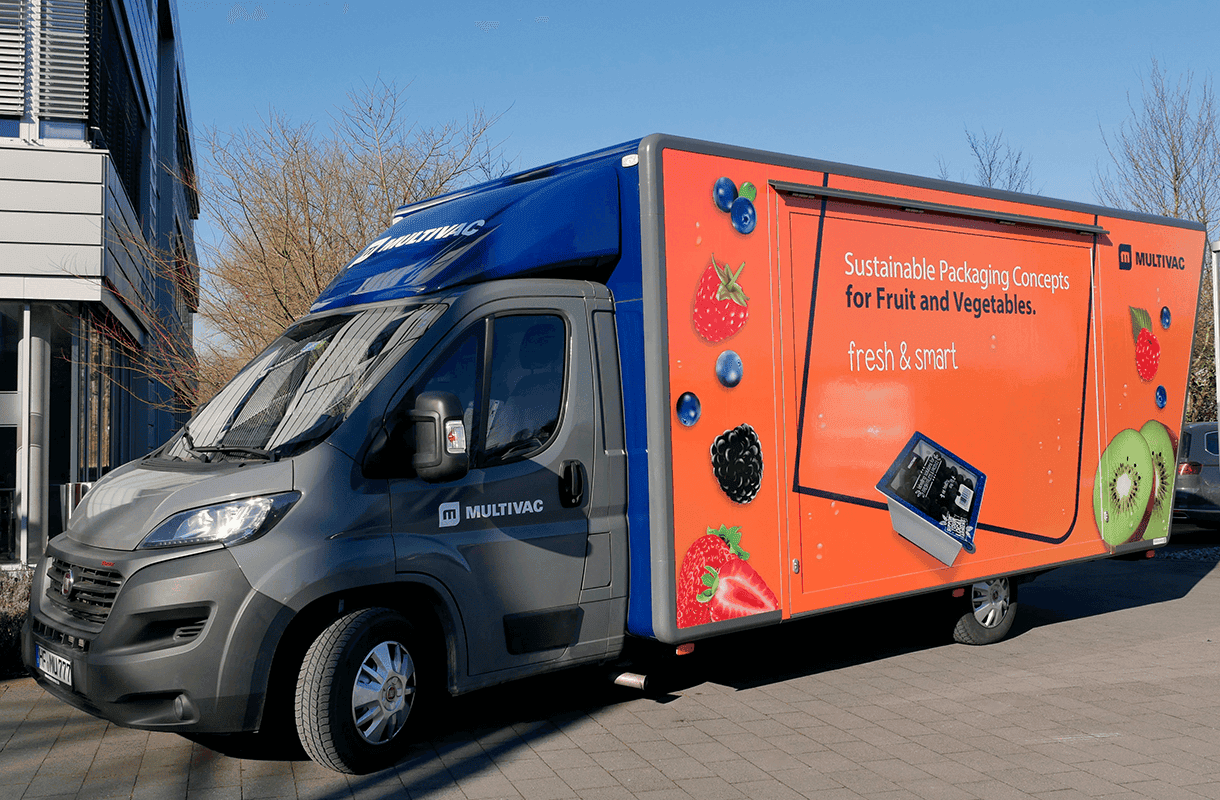

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC Website Displayed on Tablet Screen

MULTIVAC Website Displayed on Tablet Screen

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

Seafood Packaging Solutions by MULTIVAC

Seafood Packaging Solutions by MULTIVAC

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

MULTIVAC Sustainable Packaging Solutions

MULTIVAC Sustainable Packaging Solutions

Vegetable Soup Bowl on Wooden Table

Vegetable Soup Bowl on Wooden Table

MULTIVAC Future Proteins Conference Banner

MULTIVAC Future Proteins Conference Banner

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

Business Professional Portrait with Blurred Face

Business Professional Portrait with Blurred Face

Businessman in Formal Suit Portrait

Businessman in Formal Suit Portrait

Industrial Machinery Setup MULTIVAC Factory Overview

Industrial Machinery Setup MULTIVAC Factory Overview

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Food Packaging Machine Display

MULTIVAC Food Packaging Machine Display

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine High-Speed Efficiency

MULTIVAC Packaging Machine High-Speed Efficiency

Community Event in Large Tent Gathering

Community Event in Large Tent Gathering

MULTIVAC Anniversary Celebration Image

MULTIVAC Anniversary Celebration Image

Fleischer-Handwerk Award Ceremony Event Photo

Fleischer-Handwerk Award Ceremony Event Photo

MULTIVAC Trade Show Presentation

MULTIVAC Trade Show Presentation

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

Tanja Böck

Public Relations Manager

Tel: +49 8334 601-0

Mail: press@multivac-group.com