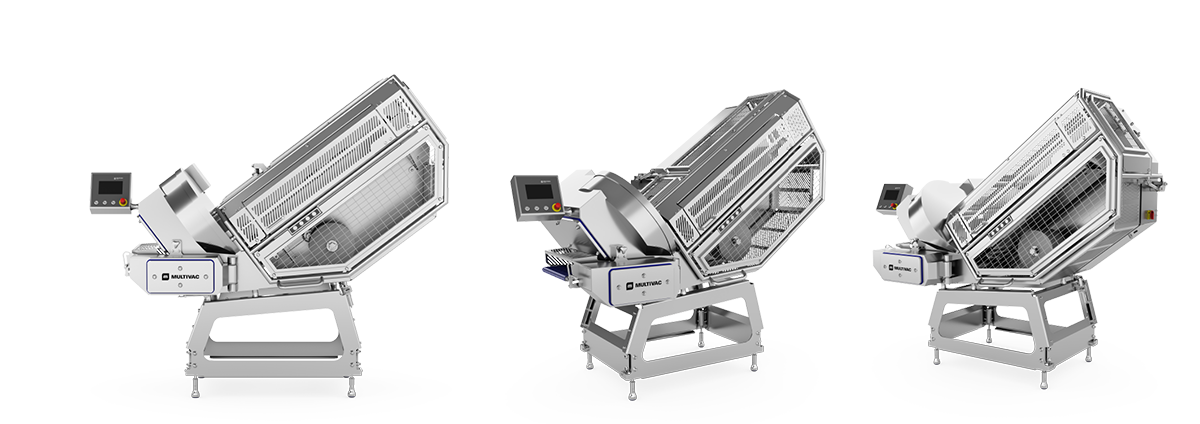

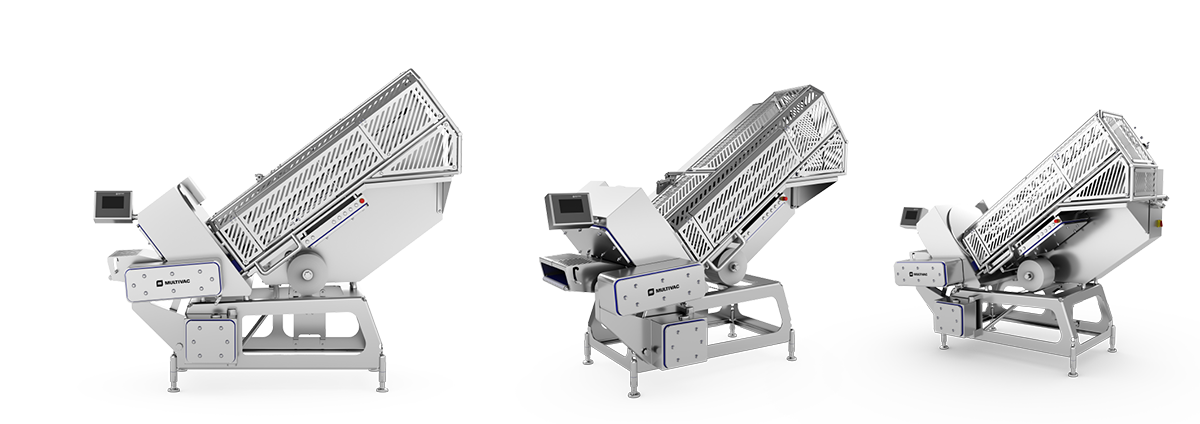

Semi-automatic slicing made simple.

Simple, affordable, robust and reliable – as part of the Professional Series is the perfect solution for small to mid-sized manufacturers.

The semi-automatic slicers are designed to process a wide variety of meats and cheeses with precise, consistent results in various product presentations, and includes adjustable cutting and blade speeds for no idle cuts. The result? high profitability with low operating and maintenance costs.

Main features

Simple slicing

Outstanding slicing results for small to mid-sized processors.

The Professional Series achieves exceptionally high-quality slices with a wide variety of food products, including cheese, bacon, sausages, deli meats, and fish. It uses a round blade and a variable cutting ratio for optimum performance over a wide range of applications, and its stacking conveyor provides consistent delivery and appearance of stacked portions.

Products with a maximum length of up to 1,000 mm can be gently and perfectly sliced, even at warmer temperatures, then deposited in the predefined arrangement or pattern for consistent results with minimal trim and give-away.

Portion Options

MULTIVAC Packaging Machine Efficiency Guide

MULTIVAC Packaging Machine Efficiency Guide

MULTIVAC Coin Stacking Machine Illustration

MULTIVAC Coin Stacking Machine Illustration

MULTIVAC Packaging Machine Efficient Design

MULTIVAC Packaging Machine Efficient Design

Maximum reliability

Maximum process reliability and flexibility, with intuitive operating convenience.

The slicers of the Professional Series can be used as a stand-alone unit or as a module within a slicing and packaging line, and downtime during recipe or format change is reduced to the absolute minimum. The operator control panel simplifies operation, reduces potential operating errors, and ensures that reliable, reproducible processes are achieved. Short set-up times, rapid conversion, and full access to the machine for easy maintenance and cleaning, guarantee high availability in everyday production. High efficiency and quality of sliced products ensure peak performance.

- S 300

- S 300 interleaving

- S 300 ext interleaving

- S 250

Everything from one source

Loading, slicing, portion feeding, packaging, printing and labelling of sliced products.

Operating in conjunction with a thermoforming packaging machine and other MULTIVAC products, the slicer forms a line featuring high output, consistent pack quality, excellent process reliability and operating convenience.

What’s the process?

Product logs are manually loaded into the slicer where they are secured by the product grippers, before being fed into the cutting chamber. A flexible slicing process enables a wide range of portion sizes and shapes to be produced, which are fed over an optional check-weigher. Incorrect weights can be identified by the marking conveyor which indicates to the loading operators which packs need to be reworked prior to loading into the packaging machine.

The packs are subsequently sealed under modified atmosphere (MAP) or vacuum, before being cut into individual packs and discharged from the packaging machine. Optional direct web printer, located at the upper web infeed and equipped with a high-performance TTO 30 thermal transfer printer, is used to print variable data on the packs. In addition to printing the best-before date on the upper web, it is also possible to apply a label automatically to the upper and lower webs.

Cost-effective, efficient, sustainable

This simplified line solution is built to compete.

The semi-automatic slicer and thermoforming packaging machine provide a robust, cost-effective solution for simple slicing and packaging applications, and is built to compete in price and performance, ideal for customers with budgetary constraints.

We are here for you!

With a packaging solution from MULTIVAC, you are not only opting for the highest quality and efficiency, but also for comprehensive support and perfect service.

Simply send us your questions, remarks or comments about slicing. Lewis Pascoe will be happy to advise you and work with you to find the right solution!