Established back in 1991, New England Seafood is a major supplier of fresh premium sustainable fish and seafood in the UK, and one of the largest importers of Yellowfin and Albacore Tuna. Based across 2 sites, Chessington and Grimsby, their customers consist of the UK’s leading supermarkets, smaller retail outlets, restaurants chains, food service markets and wholesale sectors nationwide.

New England Seafood sources over 30 species of wild and farmed fish and seafood from over 40 countries worldwide and their expertise lie in turning raw materials from trusted sources into value-adding products that are relevant and attractive for the modern consumer.

The business has the vision to inspire and show people how to enjoy fish every day and this needed to be reflected in their production process, right down to the packaging machine.

Back in 2019, a new machine was required to maximise efficiency, increase production capacity and improve presentation for a premium skin packaging solution for fresh fish portions.

New England Seafood had the experience of smaller MULTIVAC thermoforming packaging machines, but the larger MULTIVAC R 575 thermoforming packaging machine was chosen to accommodate increased volume and support future business growth needs.

The installation of the R 575 thermoformer provided New England Seafood with the latest packaging technology and was specified to ensure that the packaging process was future-proof to accept larger output volumes in the future.

Two years later, the R 575 thermoforming packaging machine continues to be an integral part of New England Seafood’s production process with consistent delivery of packs with maximum uptime and superior machine build quality.

Following the success of previous installations, the supplier also called on MULTIVAC at the end of last year to replace the existing packaging process for their whole seabass, seabream and haddock fillets with butter, which previously alternated between a swing-lid chamber machine and a smaller thermoforming packaging machine.

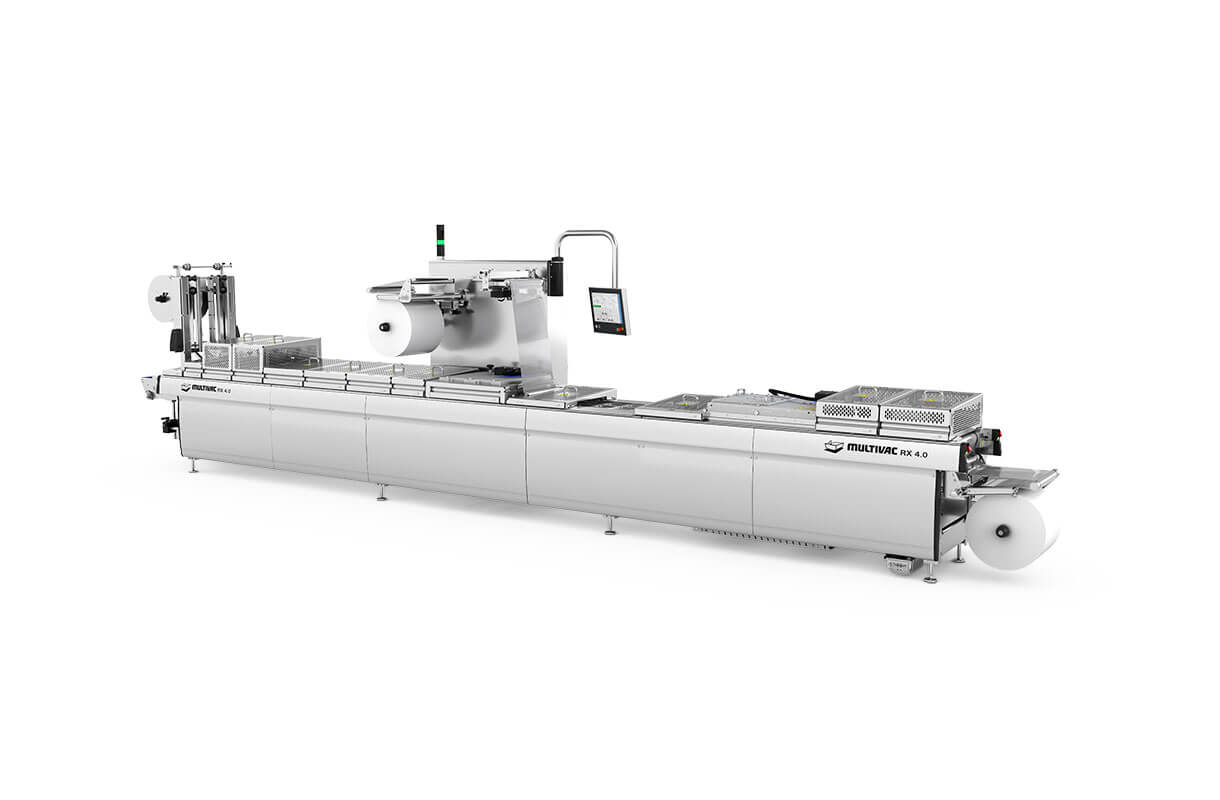

New England Seafood required a modern, more efficient solution that would not only improve the presentation and recyclability of their pack but also fit into a floor space relative to its output. After working closely with their MULTIVAC Regional Sales Representative, it was decided that MULTIVAC’s next-generation thermoformer, the high-performance RX 4.0, was best suited to the current business needs.

Future-proofing the machine was also an important consideration; MULTIVAC worked closely with New England Seafood to achieve three different pack formats on one machine. Designed to produce a fully recyclable flexible vacuum pack on board, the machine produces up to 80 packs per minute for this particular solution.

At the forefront of machine design was quick-change format functionality which allows New England Seafood to quickly change from one pack size to another without the need for time-consuming die box changes and unnecessary film wastage.

The X-line generation of thermoforming packaging machines supports the digitalisation of packaging procedures and solutions of Industry 4.0. As a result of its seamless digitalisation, comprehensive sensor system and networking with the MULTIVAC Cloud, the X-line creates a new dimension when it comes to packaging reliability, quality and performance.

Thanks to Multi-Sensor Control, the X-line thermoforming packaging machine has a level of sensor control never achieved before, even the forming and sealing dies are integrated into the sensor control via electronic sensor modules, allowing it to work constantly at the optimum operating point.

MULTIVAC Pack Pilot also enables the machine to run at an optimum level using machine control support. The machine automatically sets the parameters for optimum operation when new recipes are created using die set data and features for the pack, product and packaging material that has been selected. This allows the RX 4.0 to be easily operated without any specialist operator knowledge.

The new X-line die generation, known as X-tools, also guarantees minimal operating costs as operating reliability is increased, particularly for machines with frequent format changes.

Successfully installed at the end of 2020, the next-generation thermoforming packaging machine has since allowed New England Seafood to produce a premium looking pack while increasing the output of their production process.

MULTIVAC worked closely with New England Seafood to ensure the smooth installation of the new machine with no disruption caused to production on site.

Due to a breakdown on an older line, MULTIVAC worked closely with the engineering team on-site to expedite the installation phase of the R575 allowing them to maintain service level to the customer at a critical time.

New England Seafood has benefited from the comprehensive and sophisticated support provided by MULTIVAC UK’s Technical Service department to ensure the maximum availability and efficiency of the recently installed machines. The fish supplier also has access to the support of over 55+ Field Service Technicians, as well as a Technical Help Desk.

18.05.2023