Advancing industry standards with efficient processing equipment

June 13, 2024

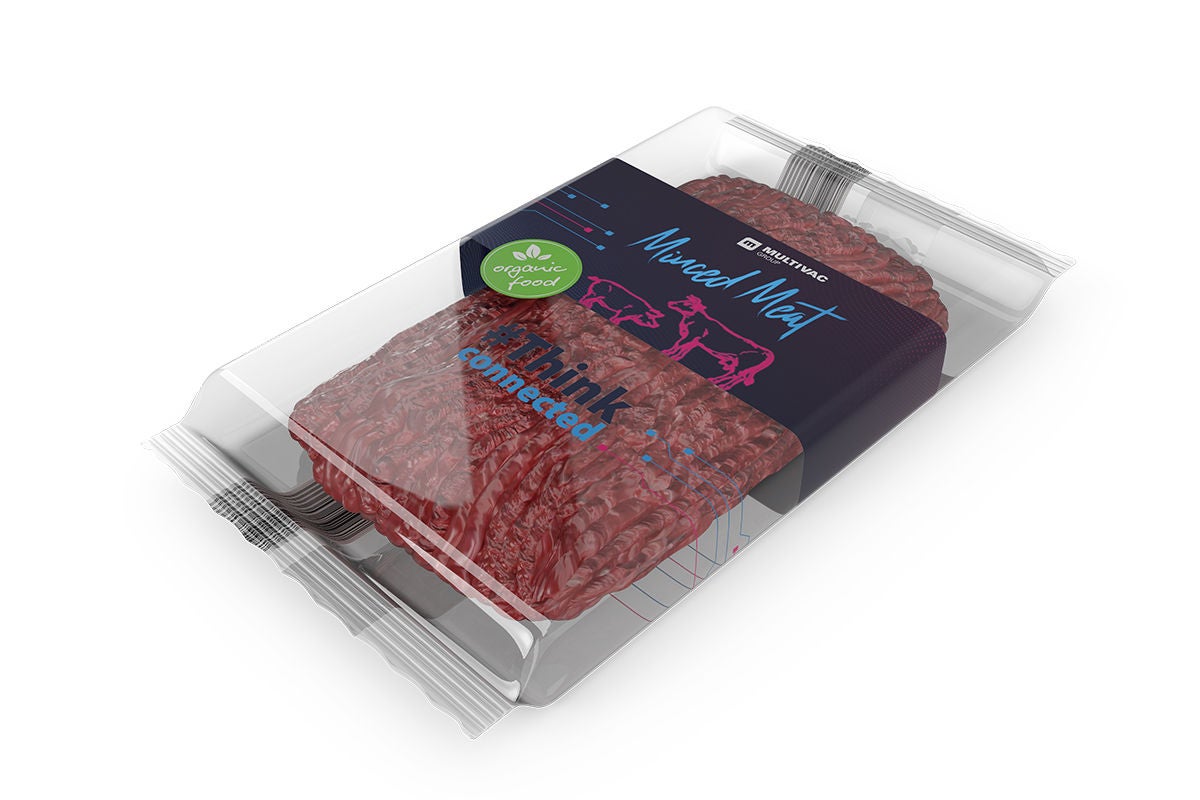

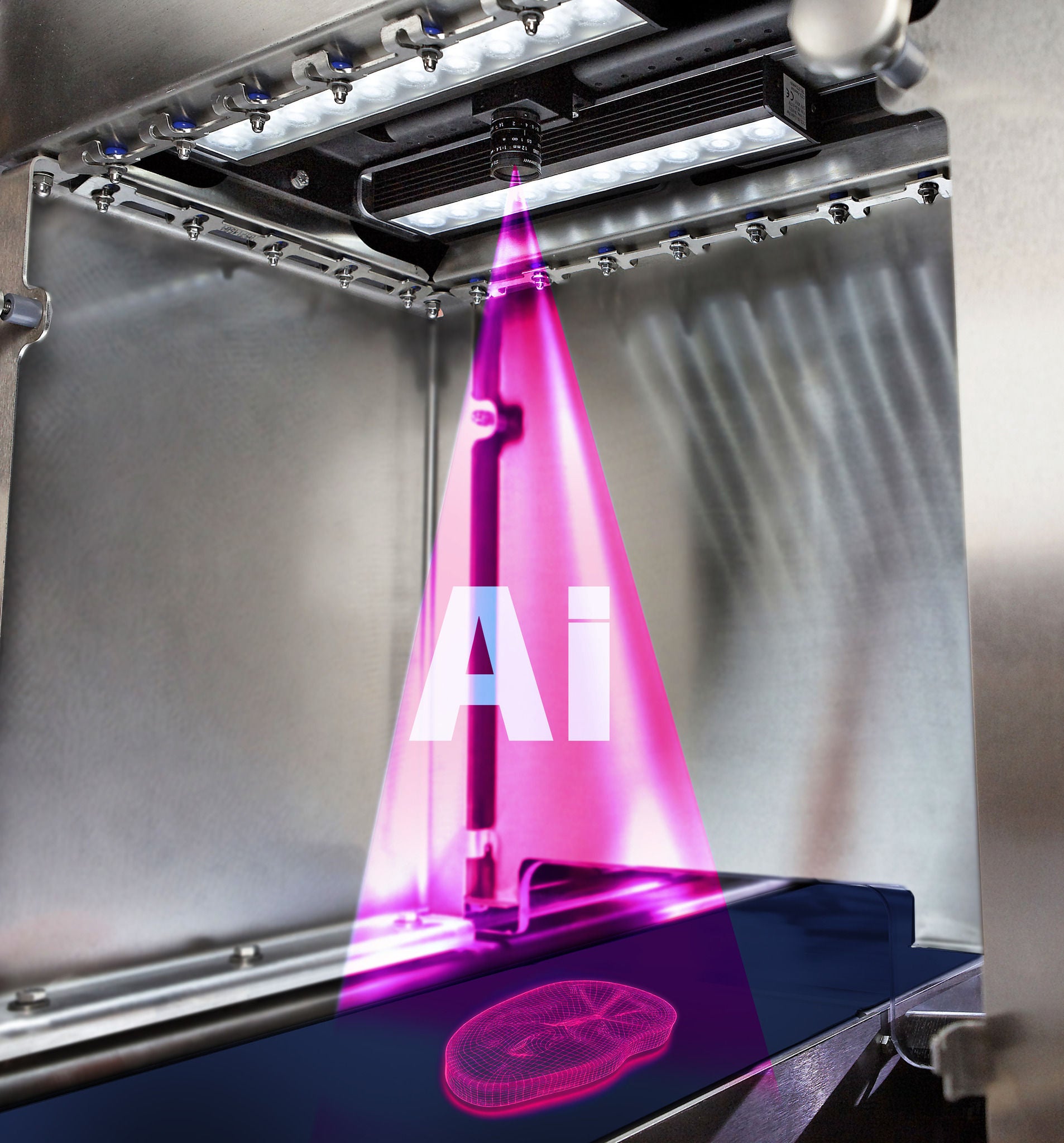

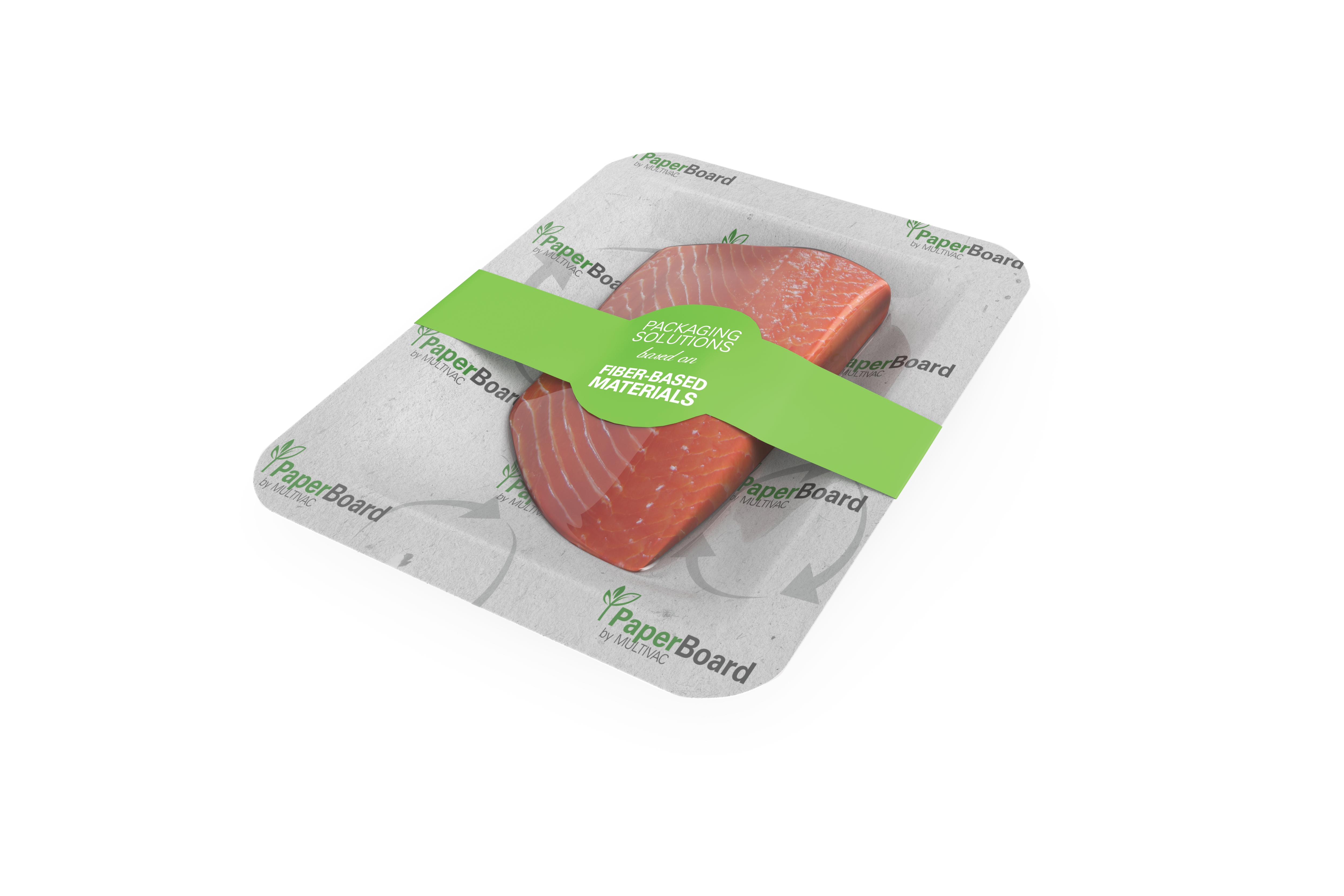

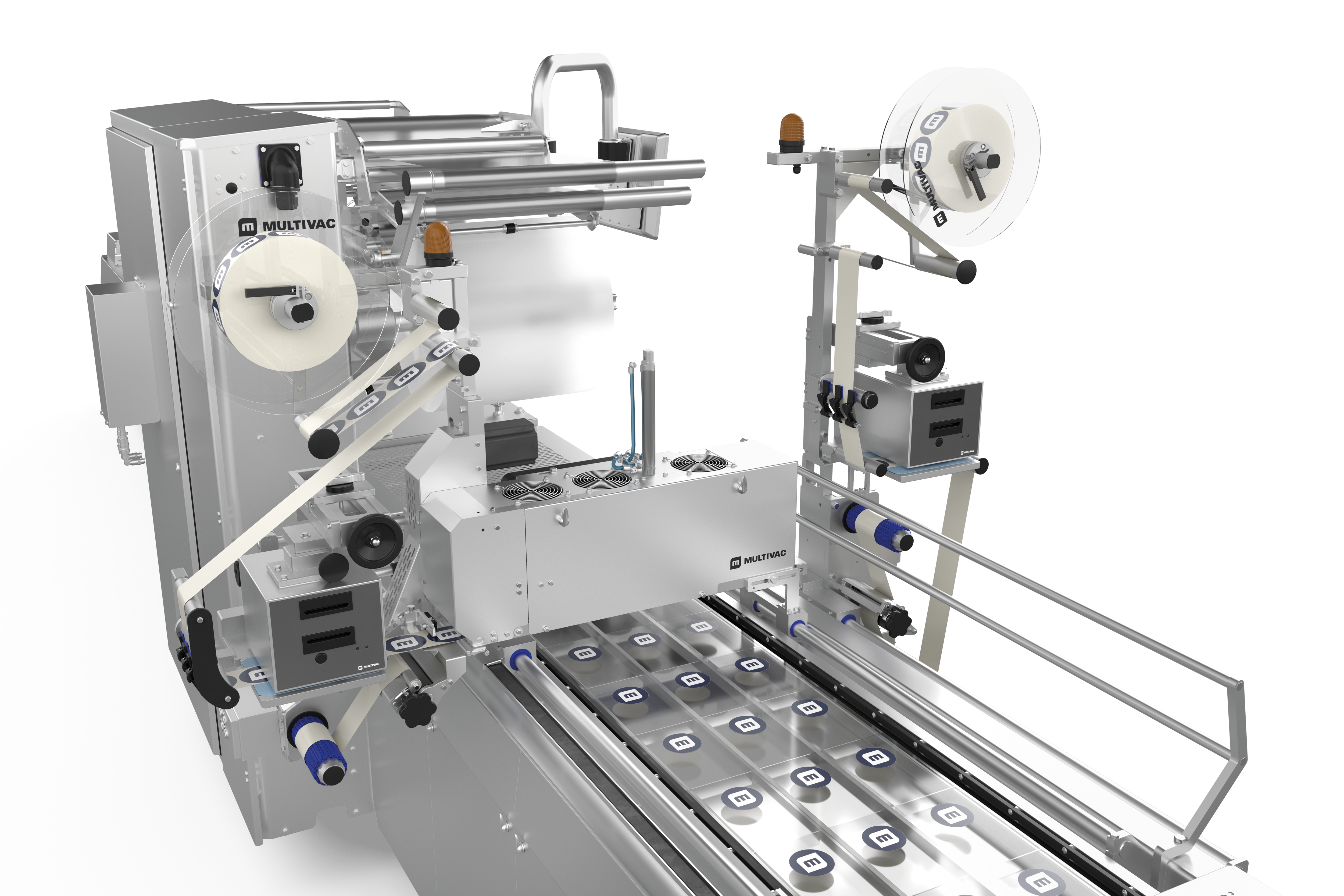

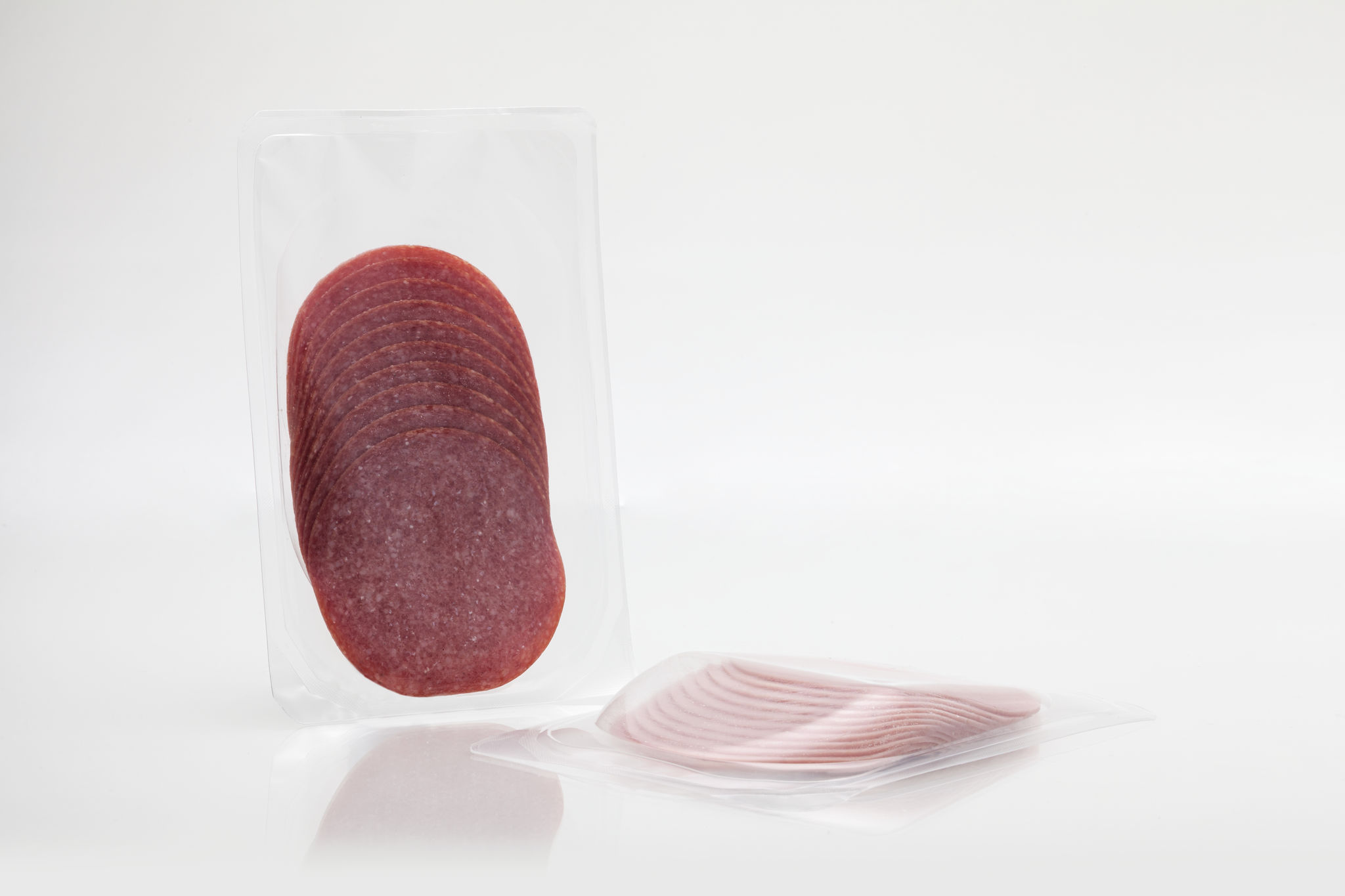

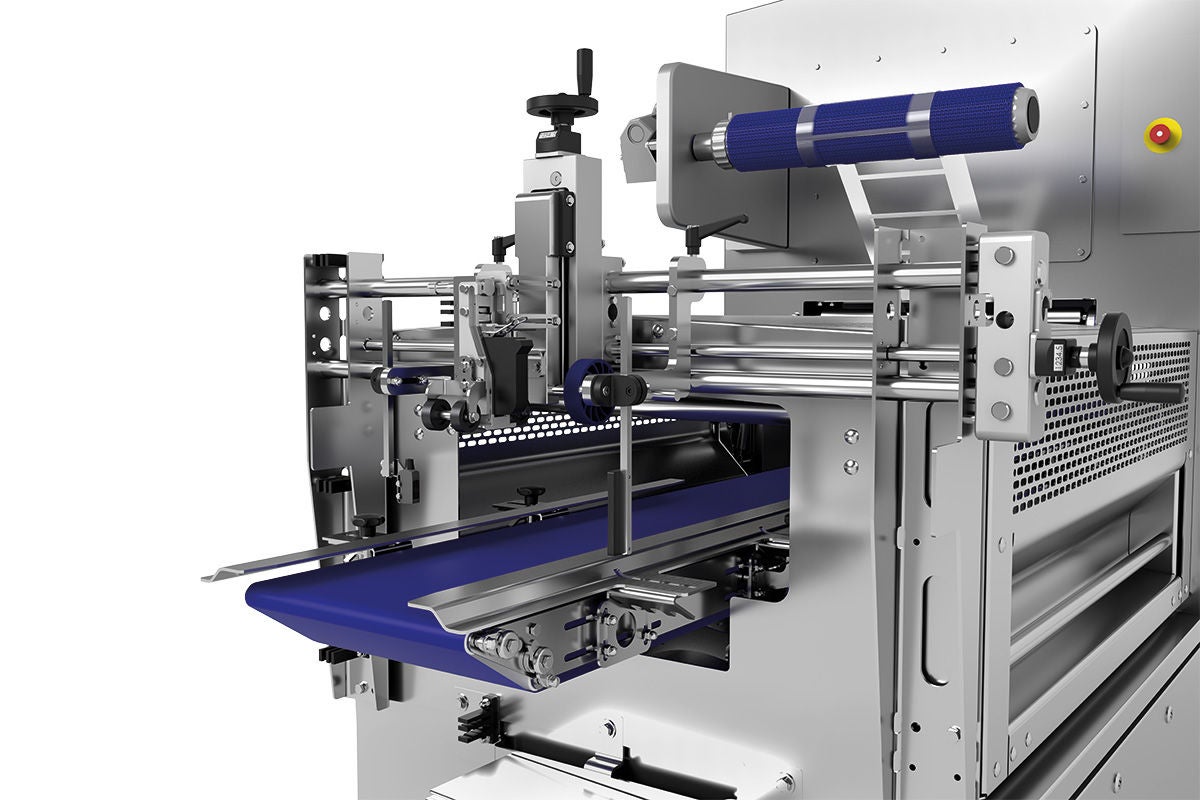

Brampton, ON, June 13, 2024 - In the competitive world of meat production, efficiency is the key to success. Producers constantly seek ways to streamline operations and reduce costs while maintaining a high-quality product for end consumers. At MULTIVAC Canada, we benefit from being at the forefront of technological advancements. While our market-leading packaging solutions are constantly evolving with the demands of our customers, we are also seeing some exciting innovations in the processing and preparation equipment we offer. From injection to mixing, manufacturers utilize advanced technology in several new ways to save both time and money.

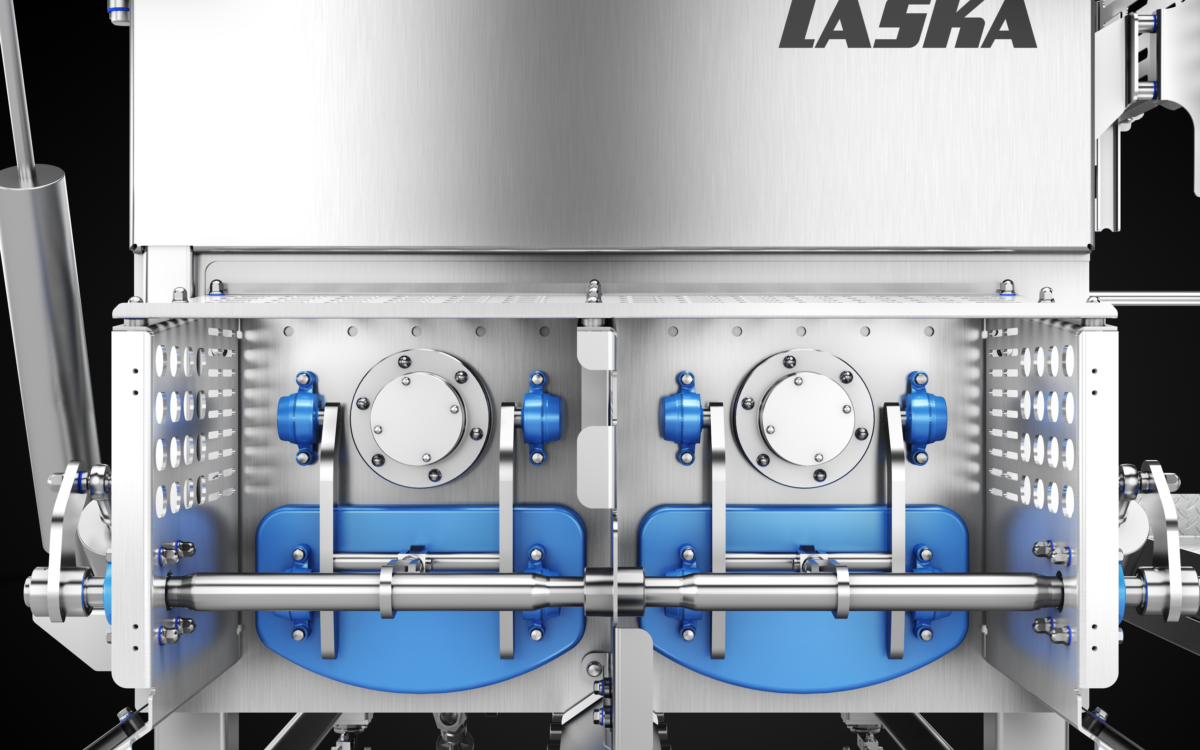

Versatility and Efficiency with LASKA Mixers

LASKA mixers are renowned for their versatility and efficiency, offering producers a well-developed solution for blending various ingredients. Whether a simple mixer or a unit designed for cooking or cooling, these mixers deliver consistent results, and the latest innovations only build off that design.

In the world of mixing, there are two main methods for achieving the perfect blend. Larger non-intermeshing paddle units offer fast unloading with longer mixing times, whereas intermeshing paddle units offer shorter mixing times but longer unloading times. Producers have always had to decide which method is best for their production, until now.

The new generation of LASKA mixers solves this problem by combining the design of both methods. These new units have intermeshing paddles, which allow for a more efficient mix; however, with independent, low-maintenance, energy-efficient drive technology, the mixing shafts can now be synchronized. With this innovation, the methods of intermeshing design and non-intermeshing design have been combined to provide both shortened mixing times and dual product discharges, which were not previously possible.

Time is money - the shorter these batch times can become, the more efficient a plant will be while freeing up critical machinery for other products.

- 1

- 2

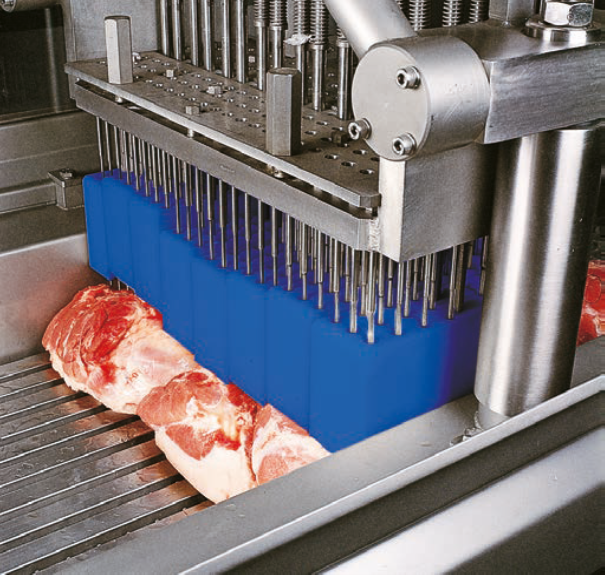

Precision Injection with METALQUIMIA Injectors

METALQUIMIA injectors are at the forefront of precision injection technology, allowing meat producers to enhance their products with unbeatable flavour, texture, and juiciness. Going against traditional injection methods, METALQUIMIA developed a system with a higher brine pressure to achieve exceptional results and retention rates. Using 12-20 small diameter holes per needle, instead of the traditional 1-2, the brine in the system is atomized, creating a spray effect that provides many previously unachievable benefits.

The results we see are remarkable in several areas. Injection accuracy is improved as the brine distribution is much more consistent, and producers benefit from less fluctuation in percentages from product to product. Drip loss rates are drastically reduced, and brine distribution increases to reach all product parts. Lastly, this technology’s injection range allows high injection levels to be achieved more efficiently. With a high-pressure spray system, we’re seeing the possibility of injection rates up to 70% in a single pass, depending on the product. This allows for previously unreachable injection rates and the possibility of doing this without multiple passes through the injector.

What does this mean to the processor? Yield is the name of the game - this technology delivers high cost and time savings by precisely controlling injection levels and distribution through your products while ensuring maximum retention rates.

- 1

- 2

Saving Time and Money: The Bottom Line

These innovations are a glimpse of what can be offered to meat producers looking for a comprehensive solution to streamline their operations or to improve profit margins. By harnessing the power of these technologies, you can save time and money, improve efficiency, reduce waste, and enhance product quality.

Can I afford these new technologies? The real question is, “Can you afford not to invest in these emerging technologies?” Each producer will have different desired outcomes, and our team of experts here at MULTIVAC Canada stands ready to show you all the latest developments.

Note: Since the beginning of 2022, MULTIVAC Canada has been the exclusive partner for preparation and processing equipment from LASKA and METALQUIMIA.

- Size

- 124 KB

- Format

- Size

- 40 MB

- Format

- png

Latest news

MUMI_Produktabbildung.indd

MUMI_Produktabbildung.indd

MULTIVAC Packaging Solutions at ACHEMA 2024

MULTIVAC Packaging Solutions at ACHEMA 2024

ANUGA FoodTec Presentation Event Highlights

ANUGA FoodTec Presentation Event Highlights

MULTIVAC Bakery Equipment Storefront Exterior

MULTIVAC Bakery Equipment Storefront Exterior

Pet Food Packaging Solutions by MULTIVAC

Pet Food Packaging Solutions by MULTIVAC

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Opening Ceremony Event

MULTIVAC Opening Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Factory Opening Ceremony Event

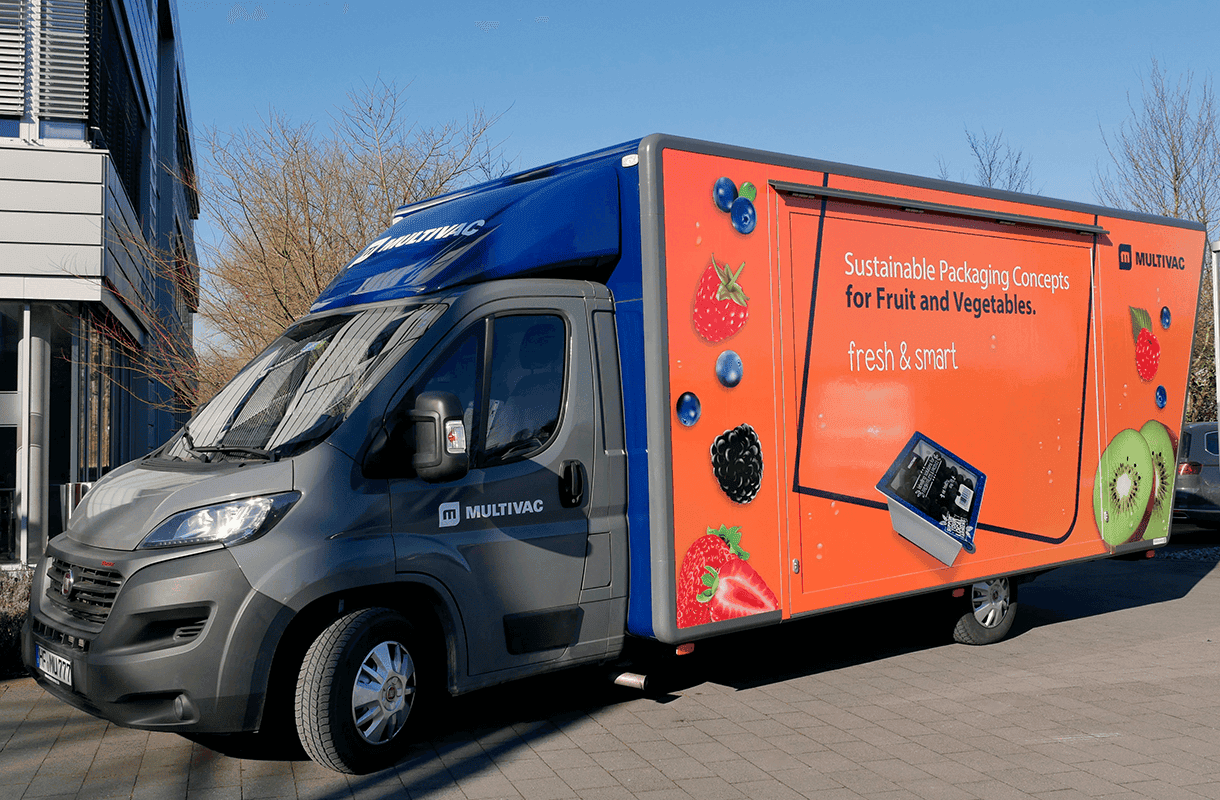

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC Website Displayed on Tablet Screen

MULTIVAC Website Displayed on Tablet Screen

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

Seafood Packaging Solutions by MULTIVAC

Seafood Packaging Solutions by MULTIVAC

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

MULTIVAC Sustainable Packaging Solutions

MULTIVAC Sustainable Packaging Solutions

Vegetable Soup Bowl on Wooden Table

Vegetable Soup Bowl on Wooden Table

MULTIVAC Future Proteins Conference Banner

MULTIVAC Future Proteins Conference Banner

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

Business Professional Portrait with Blurred Face

Business Professional Portrait with Blurred Face

Businessman in Formal Suit Portrait

Businessman in Formal Suit Portrait

Industrial Machinery Setup MULTIVAC Factory Overview

Industrial Machinery Setup MULTIVAC Factory Overview

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Food Packaging Machine Display

MULTIVAC Food Packaging Machine Display

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine High-Speed Efficiency

MULTIVAC Packaging Machine High-Speed Efficiency

Community Event in Large Tent Gathering

Community Event in Large Tent Gathering

MULTIVAC Anniversary Celebration Image

MULTIVAC Anniversary Celebration Image

Fleischer-Handwerk Award Ceremony Event Photo

Fleischer-Handwerk Award Ceremony Event Photo

MULTIVAC Trade Show Presentation

MULTIVAC Trade Show Presentation

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

Tanja Böck

Public Relations Manager

Tel: +49 8334 601-0

Mail: press@multivac-group.com