BCIT students visit MULTIVAC Canada's Innovation Centre in Richmond, B.C

May 12, 2025

First published by Ronda Payne - Western Food Processor

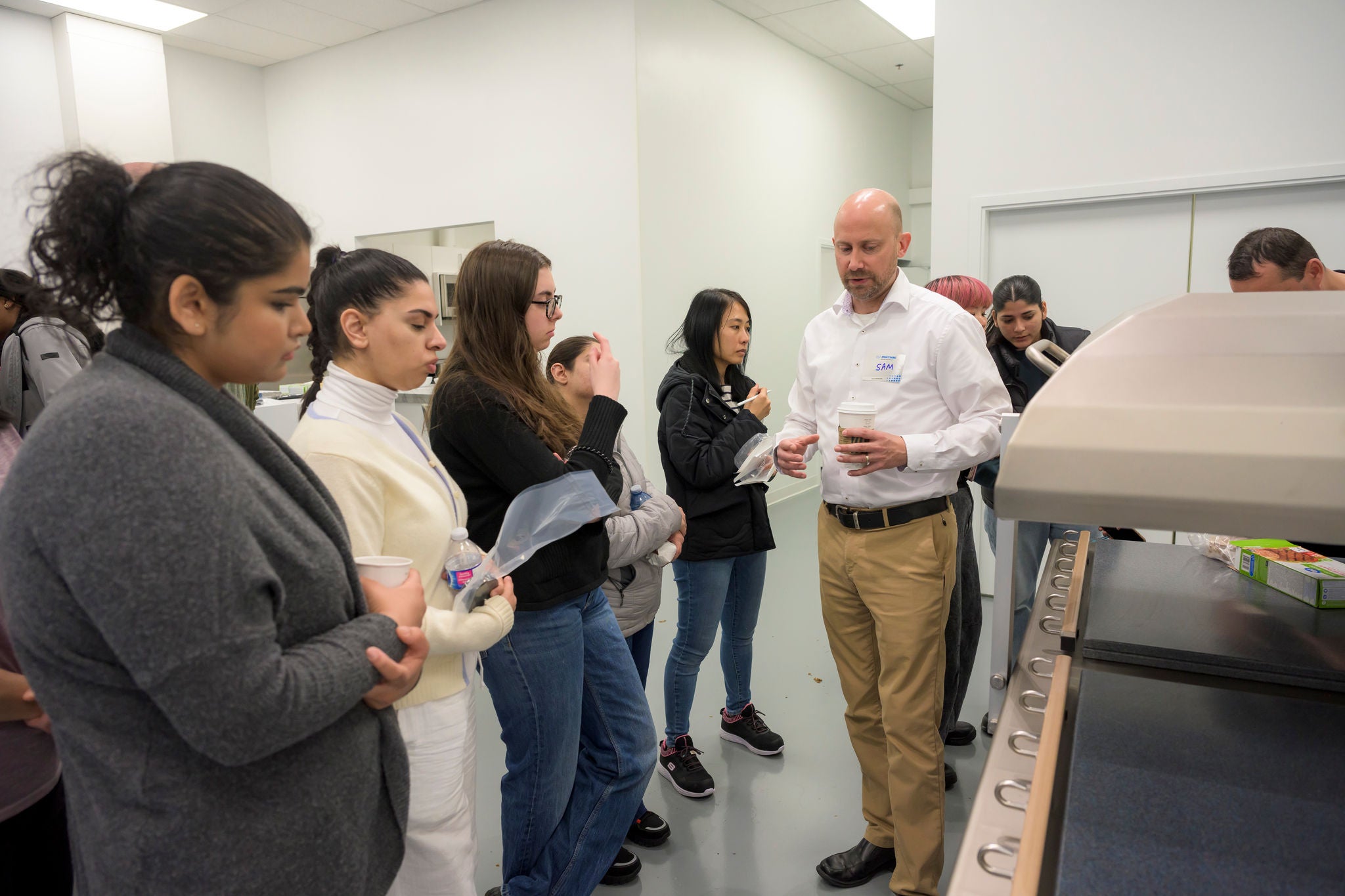

Brampton, ON – May 12, 2025: There’s nothing like the enthusiastic mind of a student with a project and passion. BCIT students from the newly renamed Food Processing, Safety and Quality two-year diploma program descended on the Richmond showroom of MULTIVAC Canada on April 15 to engage in some hands-on learning about real-world packaging tools.

Not only did they have questions about the systems and industry as a whole, but they also came with a need to learn. Their graduation depends on it.

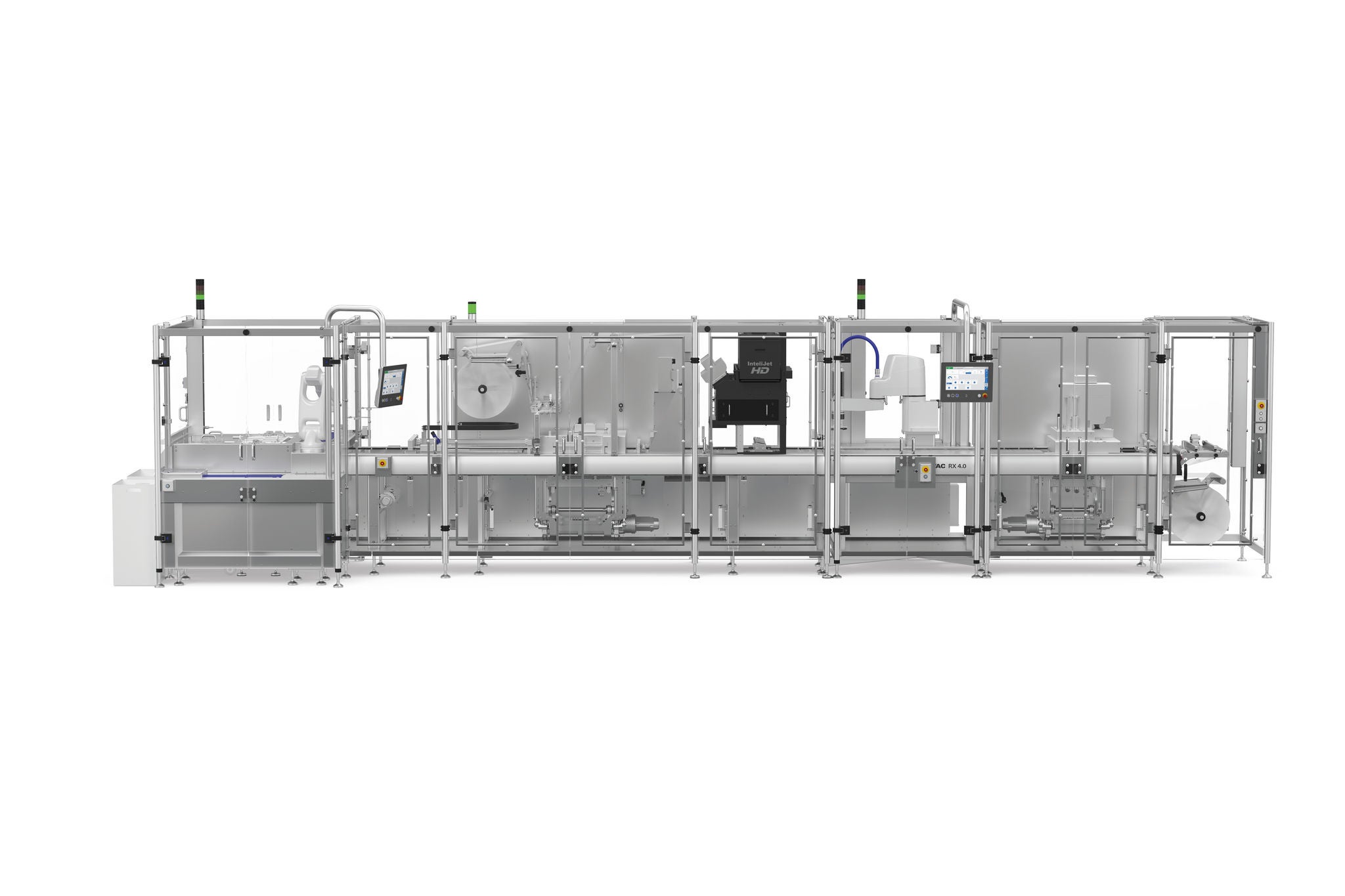

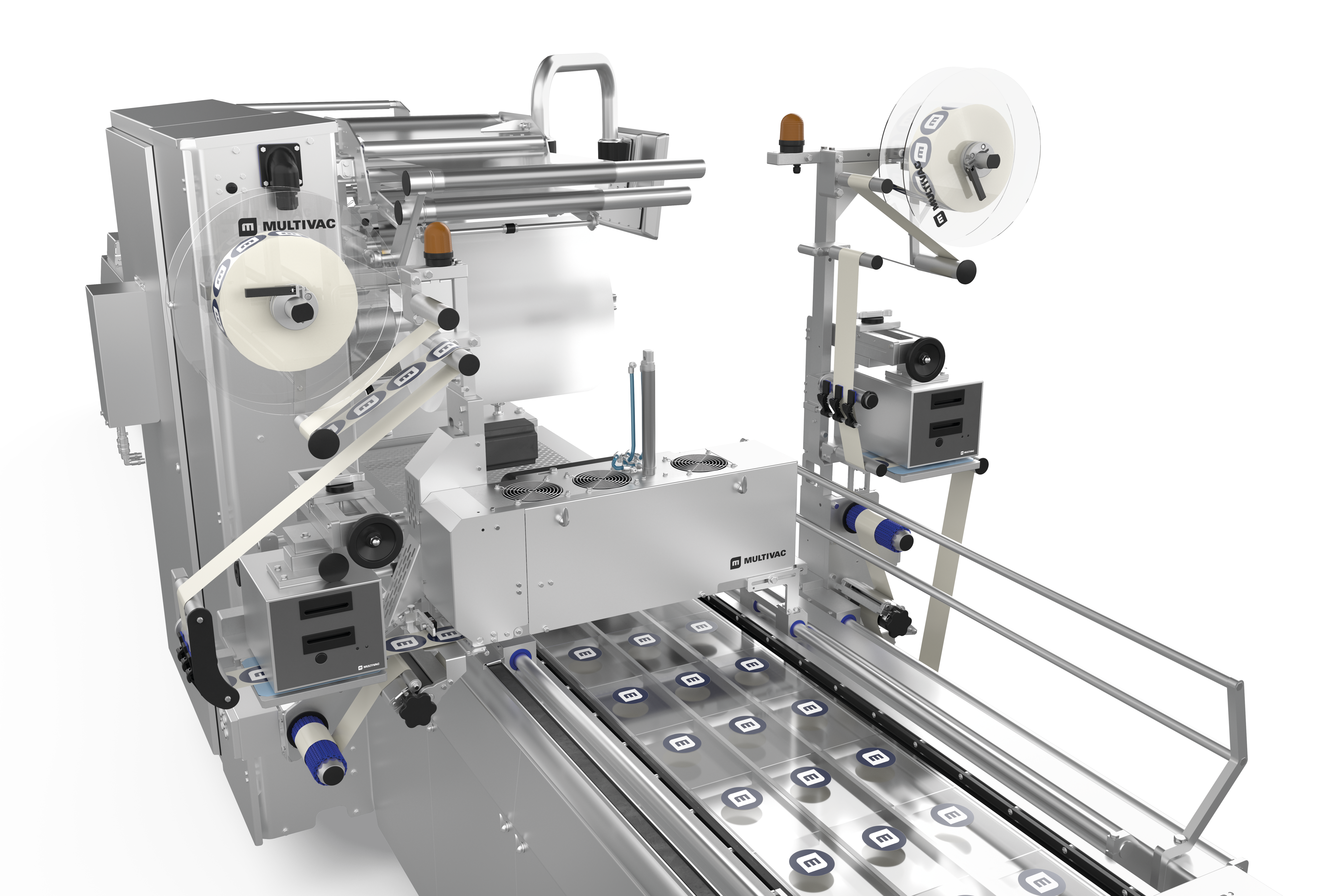

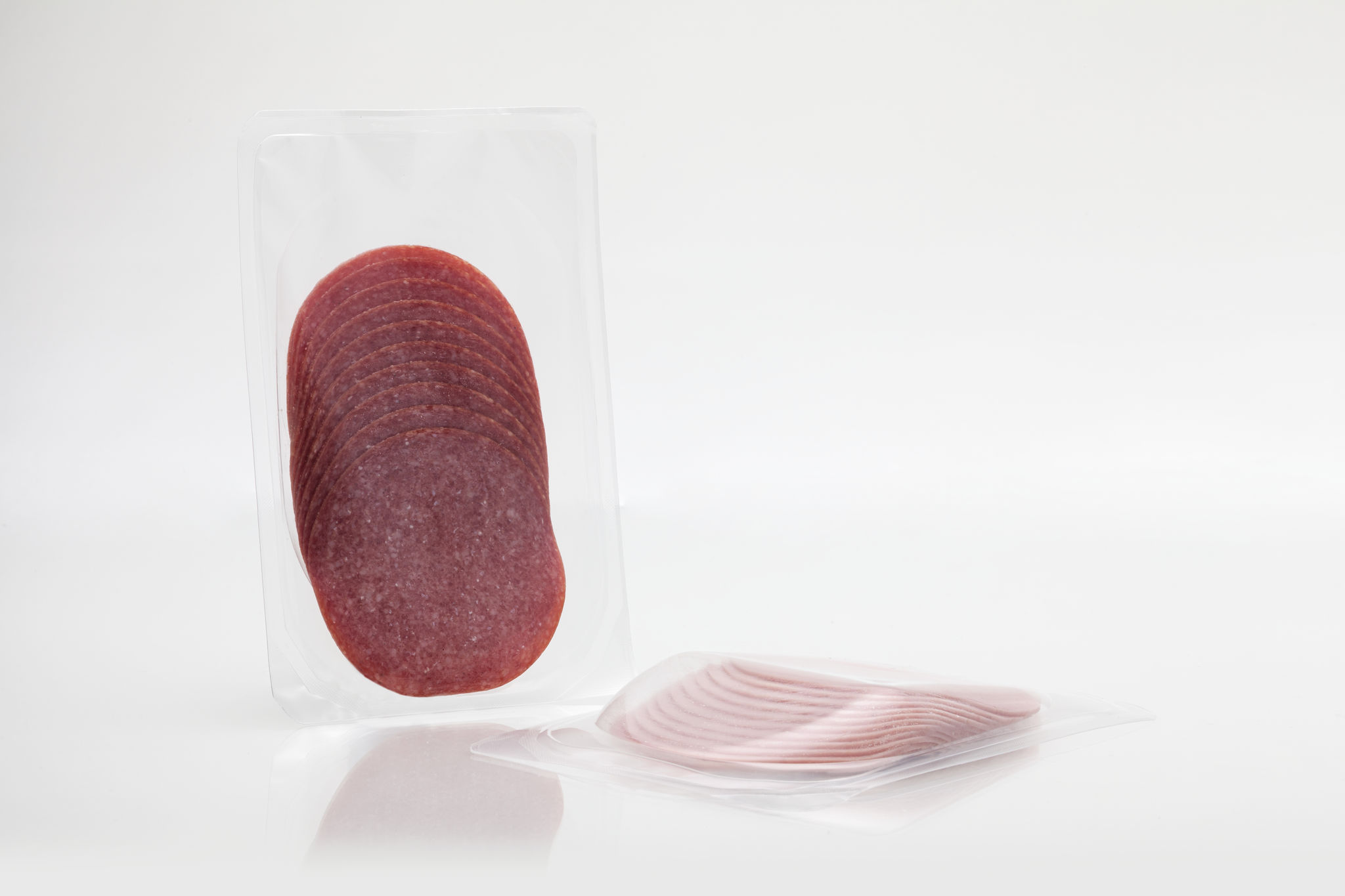

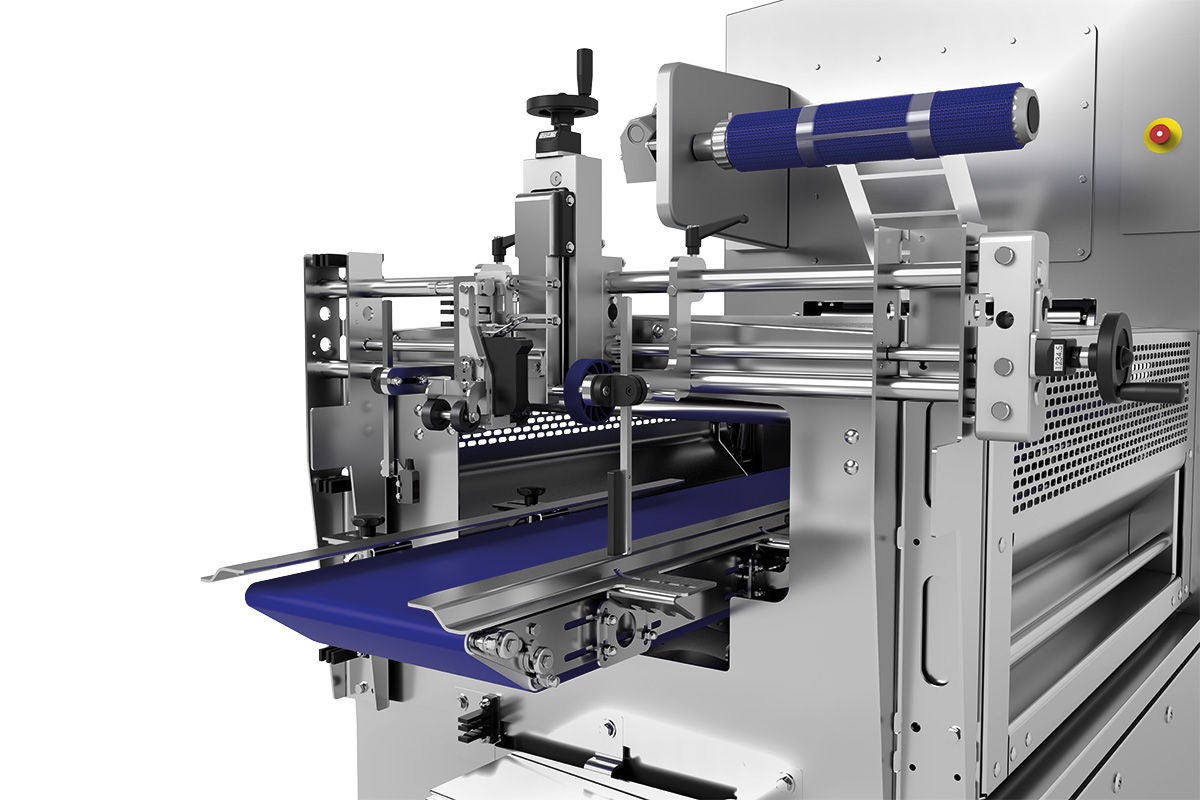

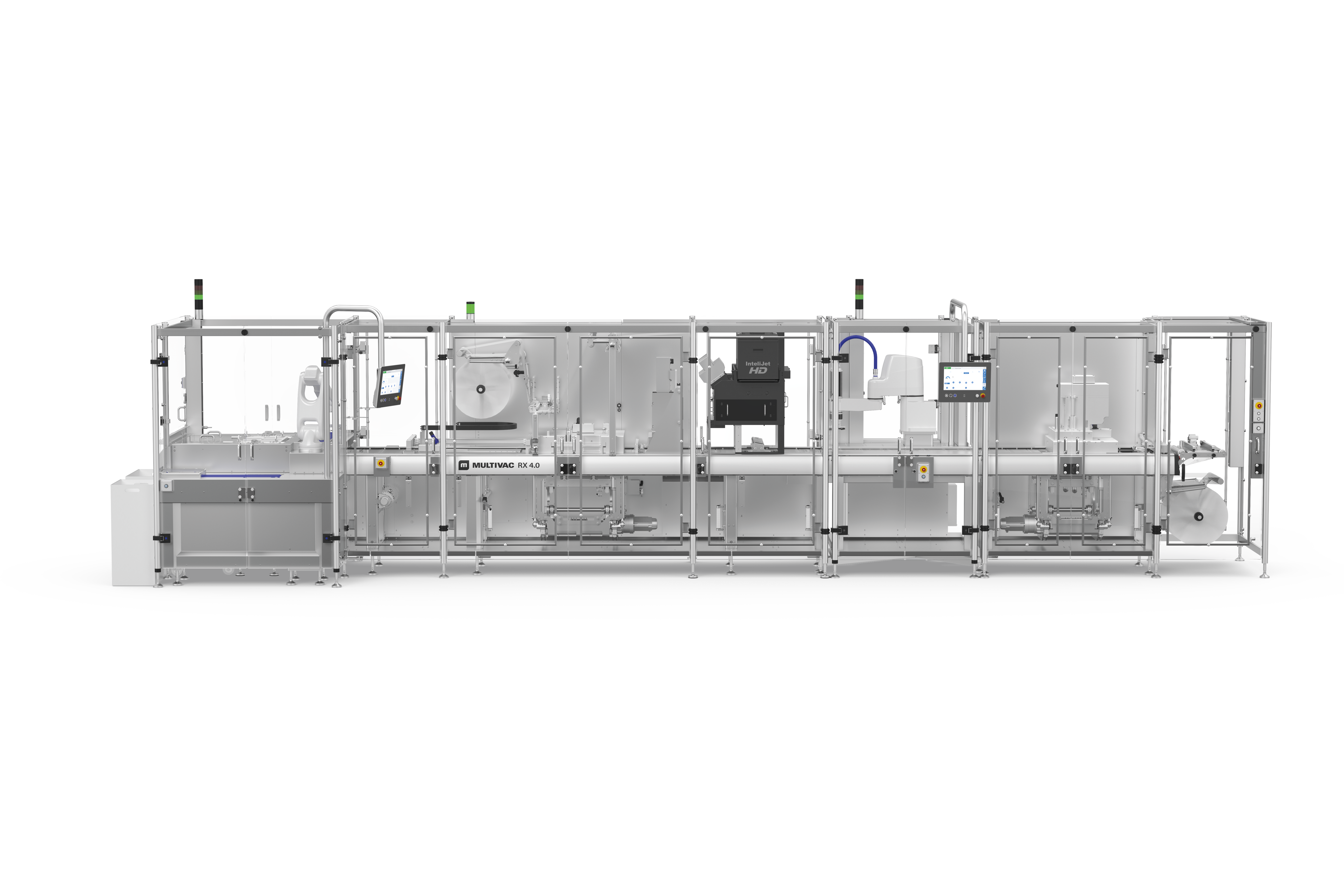

Miriam O’Donovan, one of the BCIT faculty instructors, says the group of about 30 was a mix of first- and second-year students. The second-year students had an agenda coming into MULTIVAC, a full-service supplier of processing, slicing, labelling, inspecting, and packaging technology and equipment. Each of the four second-year student groups is tasked with a complete product development project from concept to preparation for commercialization.

“We’re reformulating a plant-based patty,” O’Donovan says. “In a couple of weeks, they will present their product. They must come up with a viable product.”

A small kitchen at BCIT allows them to work on recipes and formulations, but that’s far from the final step in creating food products.

For the students, determining the best packaging and assessing MULTIVAC’s equipment and knowledge were key aspects of their afternoon. The student’s project is a real-world study of presenting the best food product possible and packaging that meets budgets, is viable, and allows marketing to attract consumers.

Student, Michelle Ma, says the visit to MULTIVAC Canada and the opportunity to ask questions are “very important.”

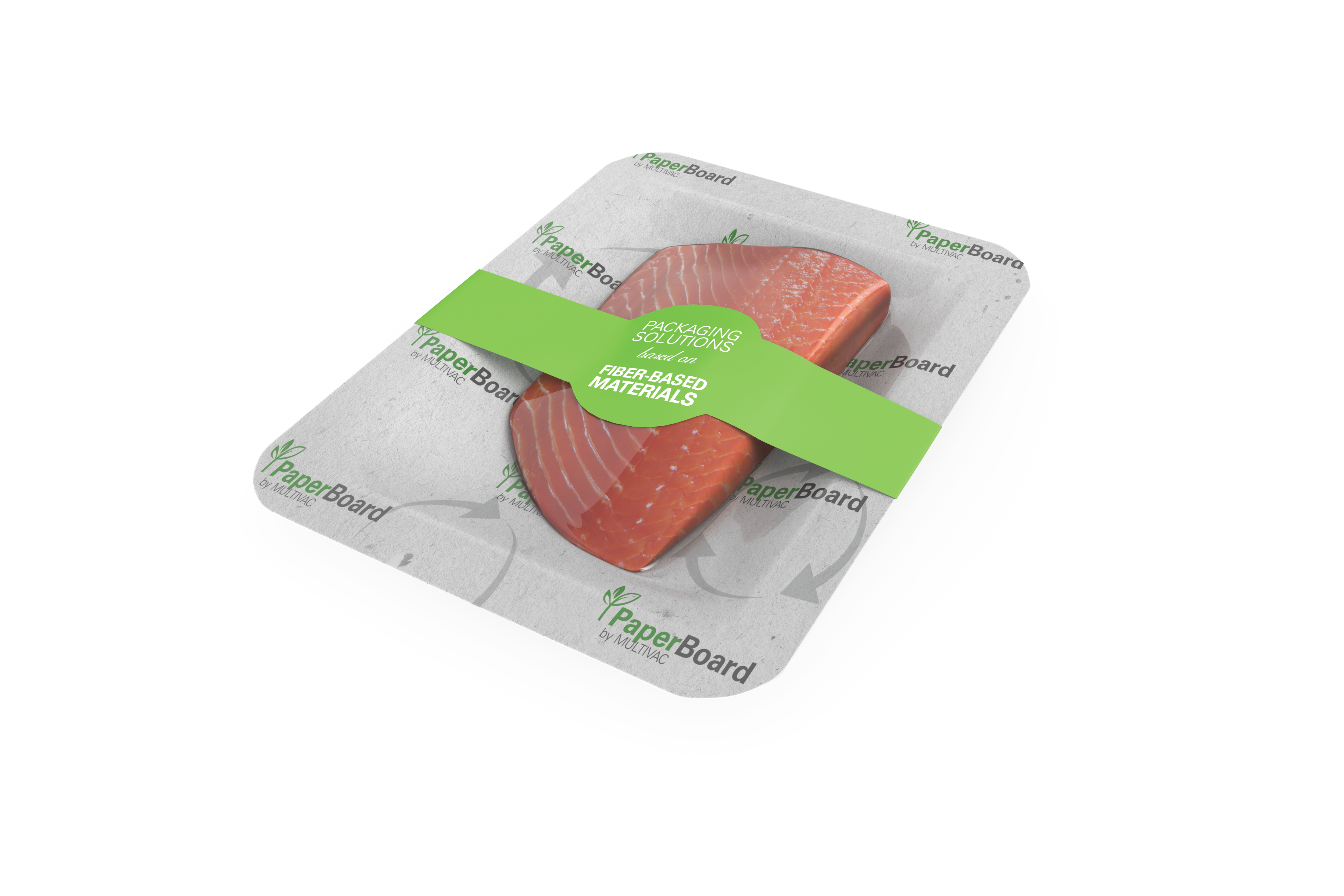

“We need to think of our packaging, and we need to consider our costing and the machinery we need,” she says. “They’re telling us about the latest technology. We can have microwaveable packaging.”

But, beyond the need to complete their assignments, the students were also gaining insight into their futures. One of Ma’s fellow team members, Ravneet Sran, valued the connections they made at MULTIVAC Canada.

“It really gave me a sense of how to use different equipment, and how the equipment can do different things,” she says. She added that the MULTIVAC team’s input could have lasting benefits for her. “They’re really helpful. I know I can always come back with questions.”

Ma hasn’t yet decided what type of role she will pursue after graduation, but Sran wants to go into product development, while another student on their team, Natalie Tam, is interested in quality assurance and control.

- 1

- 2

- 3

Sharing knowledge and creativity in the industry is something the MULTIVAC team enjoys, says Patrick McCarthy, film & materials sales manager for Western Canada.

“It’s a chance to share our individual knowledge with the students,” he says. “Some of them are surprised that we play with the food and formats.”

He motions to the cans of Play-Doh and loose hockey pucks that students were invited to use with the machines on display to simulate a burger patty, whether frozen or fresh.

“We use these things to try different ideas,” he says. “The same process we use with our customers, we are using with the students.”

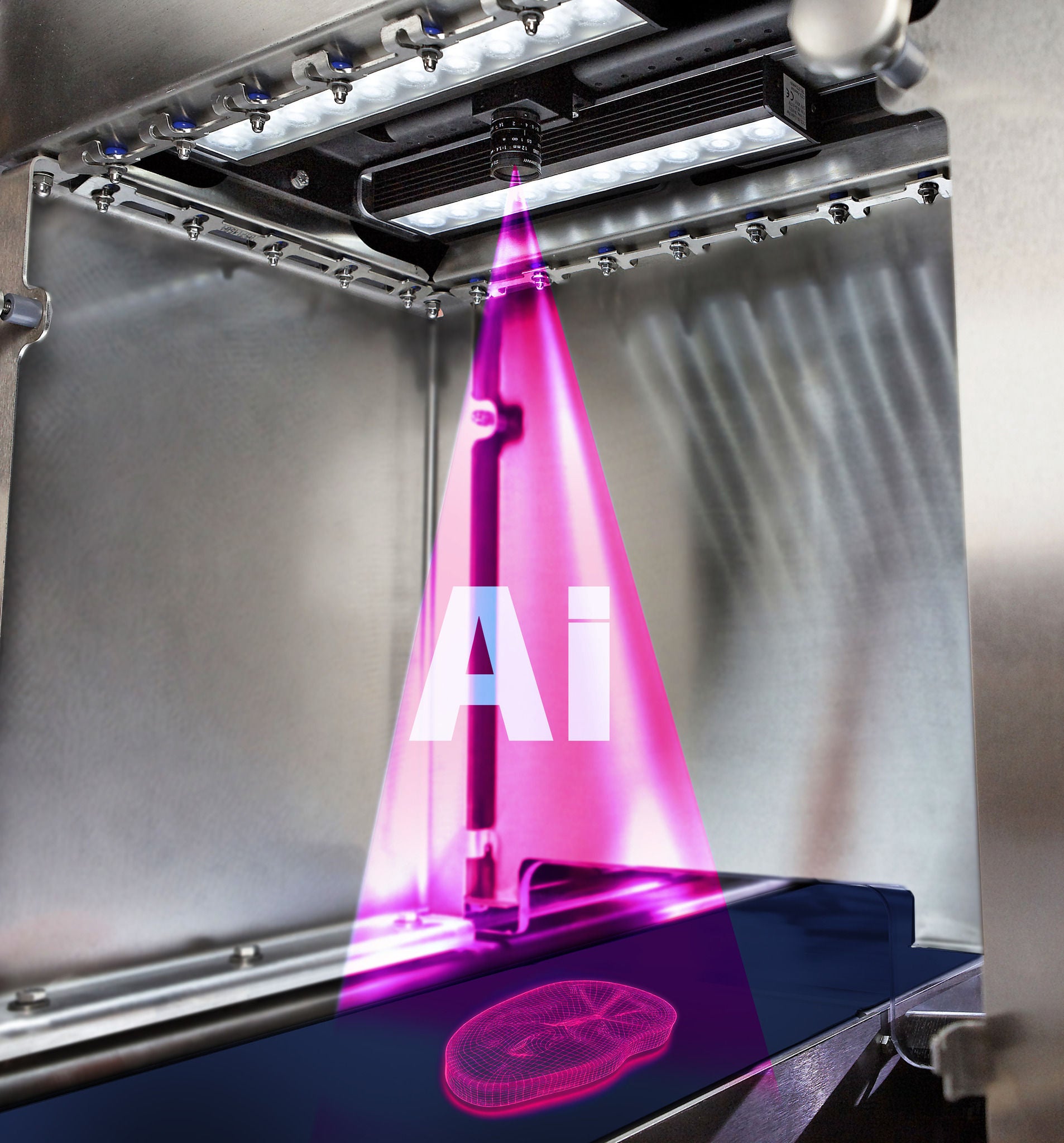

Students also watched demonstrations of other equipment around the room, like the tray sealer and chamber machines. The MULTIVAC team took the time to demonstrate the equipment’s functionality, flexibility, and ability to meet the students’ project needs.

Before students began exploring and asking specific questions, McCarthy and Sam Nosek, regional sales manager with MULTIVAC Canada, spoke about what different products can and can’t do and dispelled some assumptions the students had.

“You can use microwaveable, bakeable and recyclable packaging based on the products’ market needs. Paper, plastic, and foil - the options are almost endless,” says McCarthy. “Sometimes what you believe you can’t use it for is not true.”

“There are opportunities to create packages with various lid types,” says Nosek. “Some are breathable. There are varying rates depending on the type of produce.”

He added that the event was an opportunity to help the next generation of leaders learn more about the industry they are heading into. They could see the equipment, understand it and have applicable, real-world knowledge for the next stage of their careers.

- 1

- 2

- 3

- 4

“The two-year program is preparing them for this,” says O’Donovan.

While packaging is only part of the educational journey, it’s a component of nearly everything students learn.

“We actually expose them to commissary kitchens and farmers’ markets,” she says. “We take them on a trip to a grocery store to see products in the market. We’re trying to prepare them to go out into the industry, so they’re not in awe when they go into industry.”

She says that applied learning in the program is second-to-none because they must take theory into practical steps to complete their projects. This is their final exam per se. There isn’t a written test. Instead, it’s a group of industry leaders assessing the student groups’ projects and reports.

After graduation, they will likely pursue careers in research and development, quality control and quality assurance and even entrepreneurship. Some past students have taken their ideas to market after completing the program.

“They get the business pieces, they’re learning management, business concepts, pricing and developing a budget is part of that,” says O’Donovan.

Erin Friesen is the head of the Food Processing, Safety, and Quality Program. She considers the visit to MULTIVAC Canada essential to student learning.

“I teach the packaging component, and it’s a very boring lecture,” she says. “Actually, seeing the materials and feeling the materials is a very important way to learn.”

She also regards BCIT’s relationship with MULTIVAC Canada as a foundational component of the student’s future. The program is always looking for additional partnerships to support the up-and-coming workforce.

“There’s a lot of networking in this industry as well,” he says. “There’s quite a community of people and companies who have expertise that can help tackle any challenge. Have fun with it and solve the problems you encounter by leveraging your network.” Says Nosek

Relationships are foundational in any industry, but for those just learning about food processing and packaging, hearing from people who are leading the way brings formal education into focus. With support from companies like MULTIVAC Canada, BCIT’s students will be well prepared for their next journey.

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

Latest news

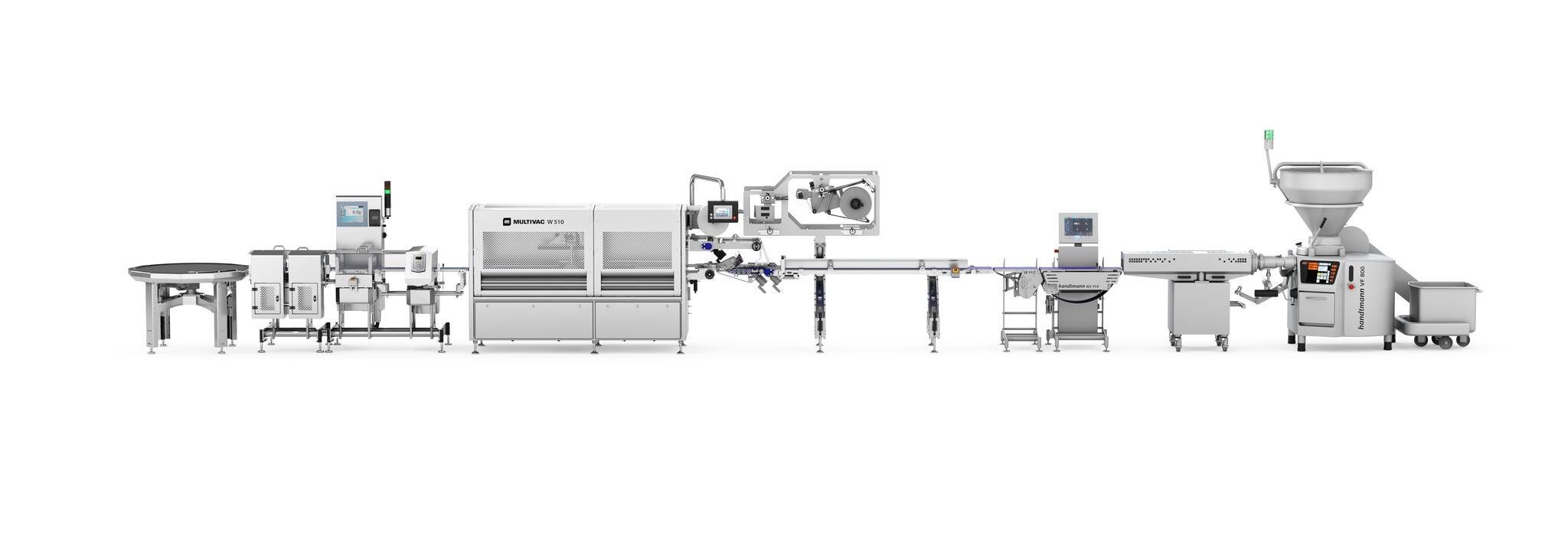

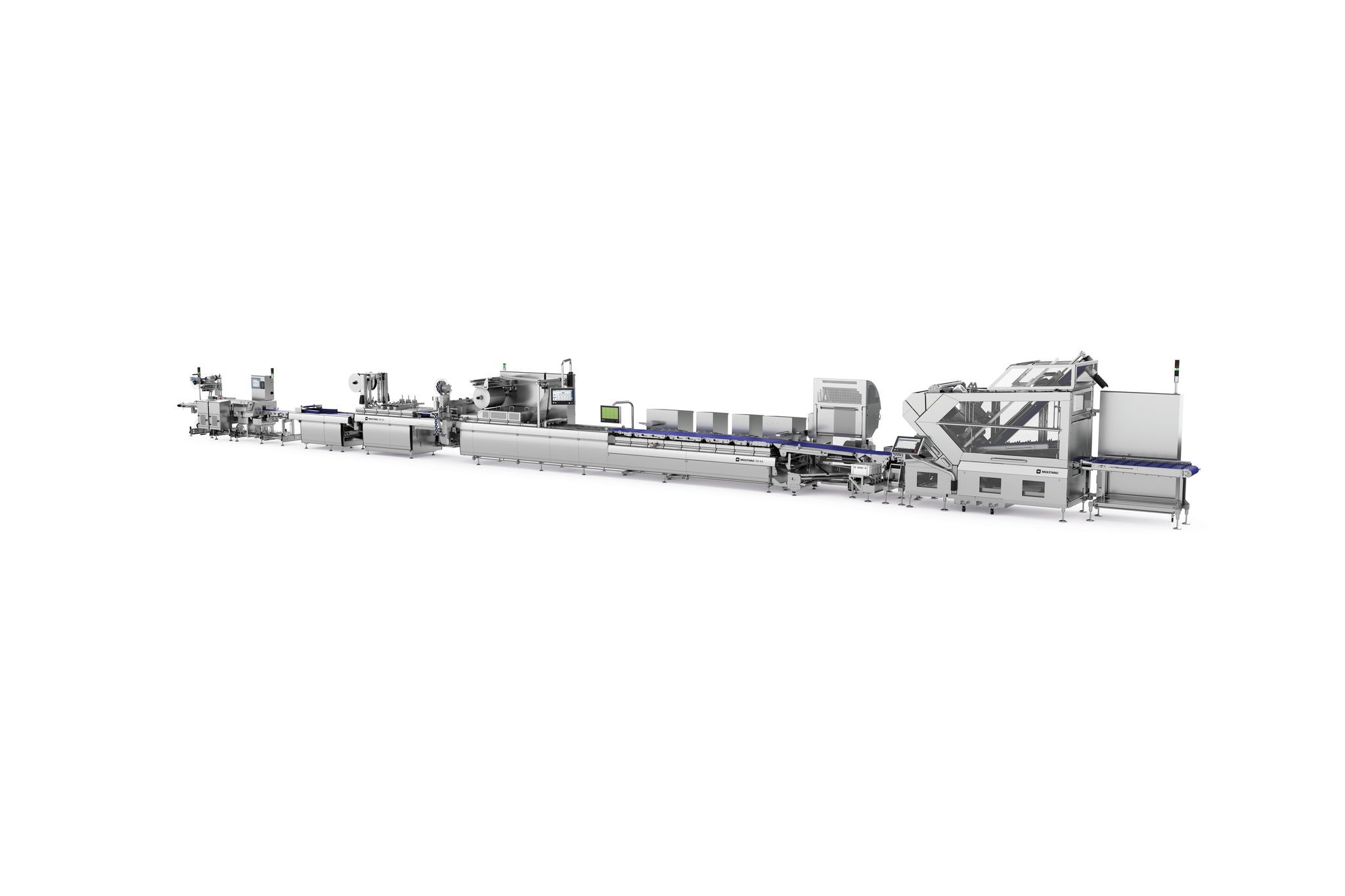

MUMI_Produktabbildung.indd

MUMI_Produktabbildung.indd

MULTIVAC Packaging Solutions at ACHEMA 2024

MULTIVAC Packaging Solutions at ACHEMA 2024

ANUGA FoodTec Presentation Event Highlights

ANUGA FoodTec Presentation Event Highlights

MULTIVAC Bakery Equipment Storefront Exterior

MULTIVAC Bakery Equipment Storefront Exterior

Pet Food Packaging Solutions by MULTIVAC

Pet Food Packaging Solutions by MULTIVAC

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

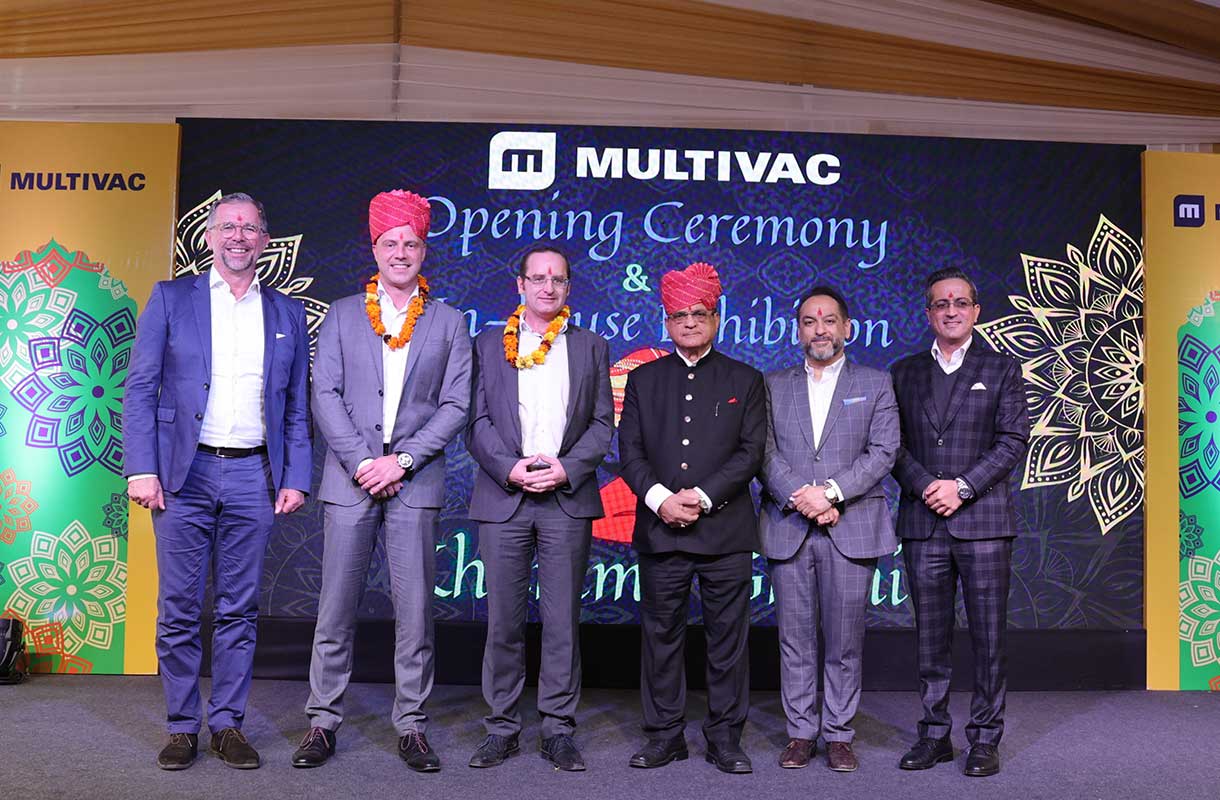

MULTIVAC Opening Ceremony Event

MULTIVAC Opening Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC Sustainable Packaging for Fresh Produce

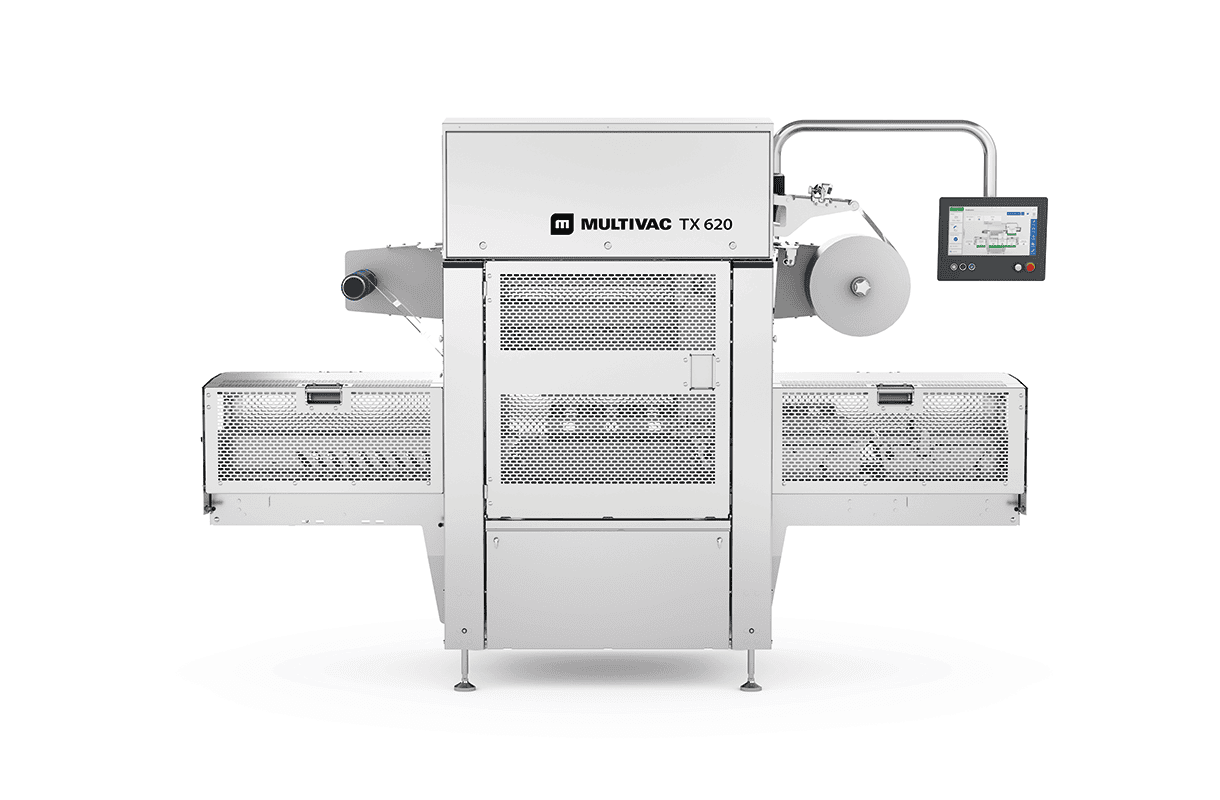

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC Website Displayed on Tablet Screen

MULTIVAC Website Displayed on Tablet Screen

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

Seafood Packaging Solutions by MULTIVAC

Seafood Packaging Solutions by MULTIVAC

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

MULTIVAC Sustainable Packaging Solutions

MULTIVAC Sustainable Packaging Solutions

Vegetable Soup Bowl on Wooden Table

Vegetable Soup Bowl on Wooden Table

MULTIVAC Future Proteins Conference Banner

MULTIVAC Future Proteins Conference Banner

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

Business Professional Portrait with Blurred Face

Business Professional Portrait with Blurred Face

Businessman in Formal Suit Portrait

Businessman in Formal Suit Portrait

Industrial Machinery Setup MULTIVAC Factory Overview

Industrial Machinery Setup MULTIVAC Factory Overview

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Food Packaging Machine Display

MULTIVAC Food Packaging Machine Display

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine High-Speed Efficiency

MULTIVAC Packaging Machine High-Speed Efficiency

Community Event in Large Tent Gathering

Community Event in Large Tent Gathering

MULTIVAC Anniversary Celebration Image

MULTIVAC Anniversary Celebration Image

Fleischer-Handwerk Award Ceremony Event Photo

Fleischer-Handwerk Award Ceremony Event Photo

MULTIVAC Trade Show Presentation

MULTIVAC Trade Show Presentation

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

Tanja Böck

Public Relations Manager

Tel: +49 8334 601-0

Mail: press@multivac-group.com