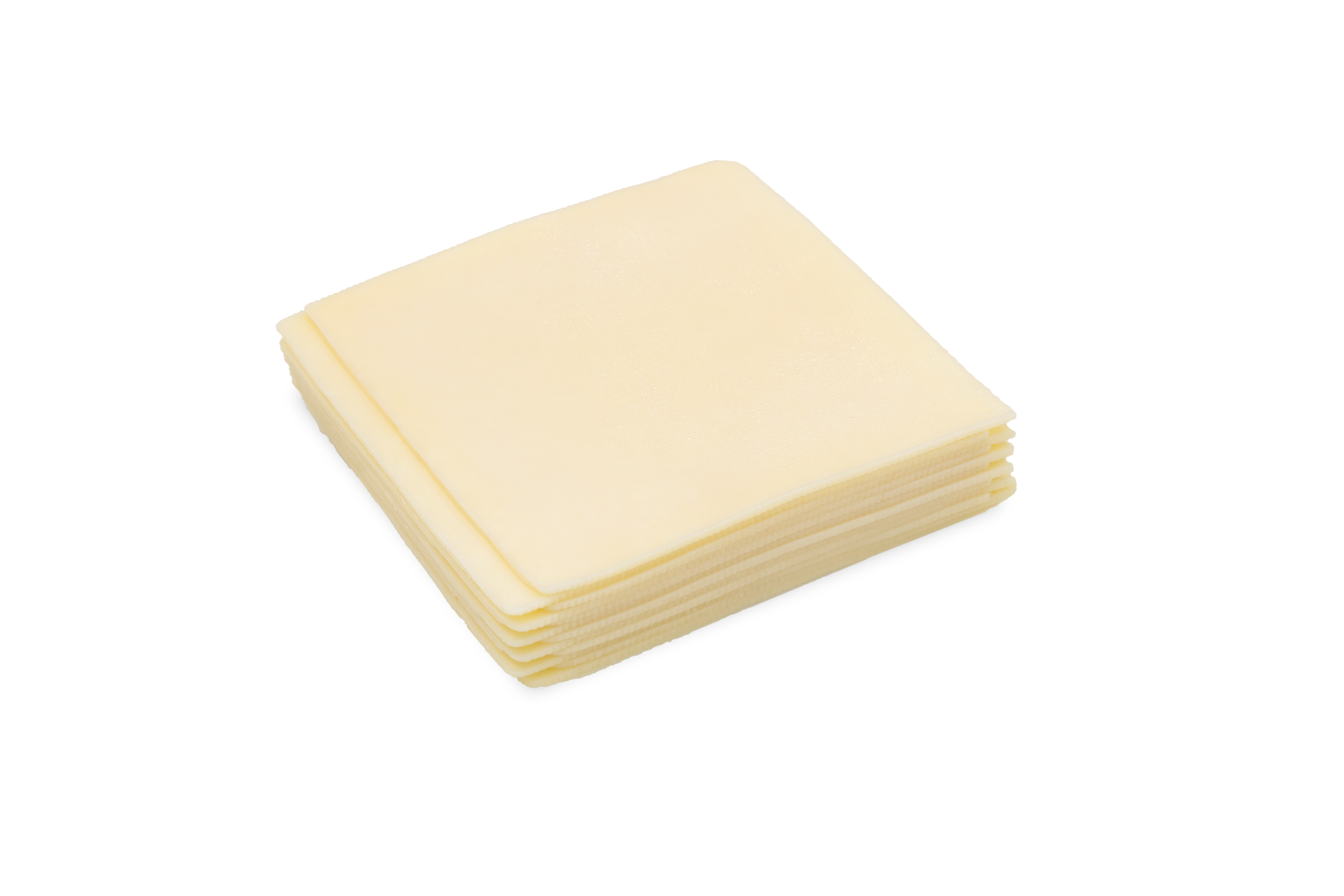

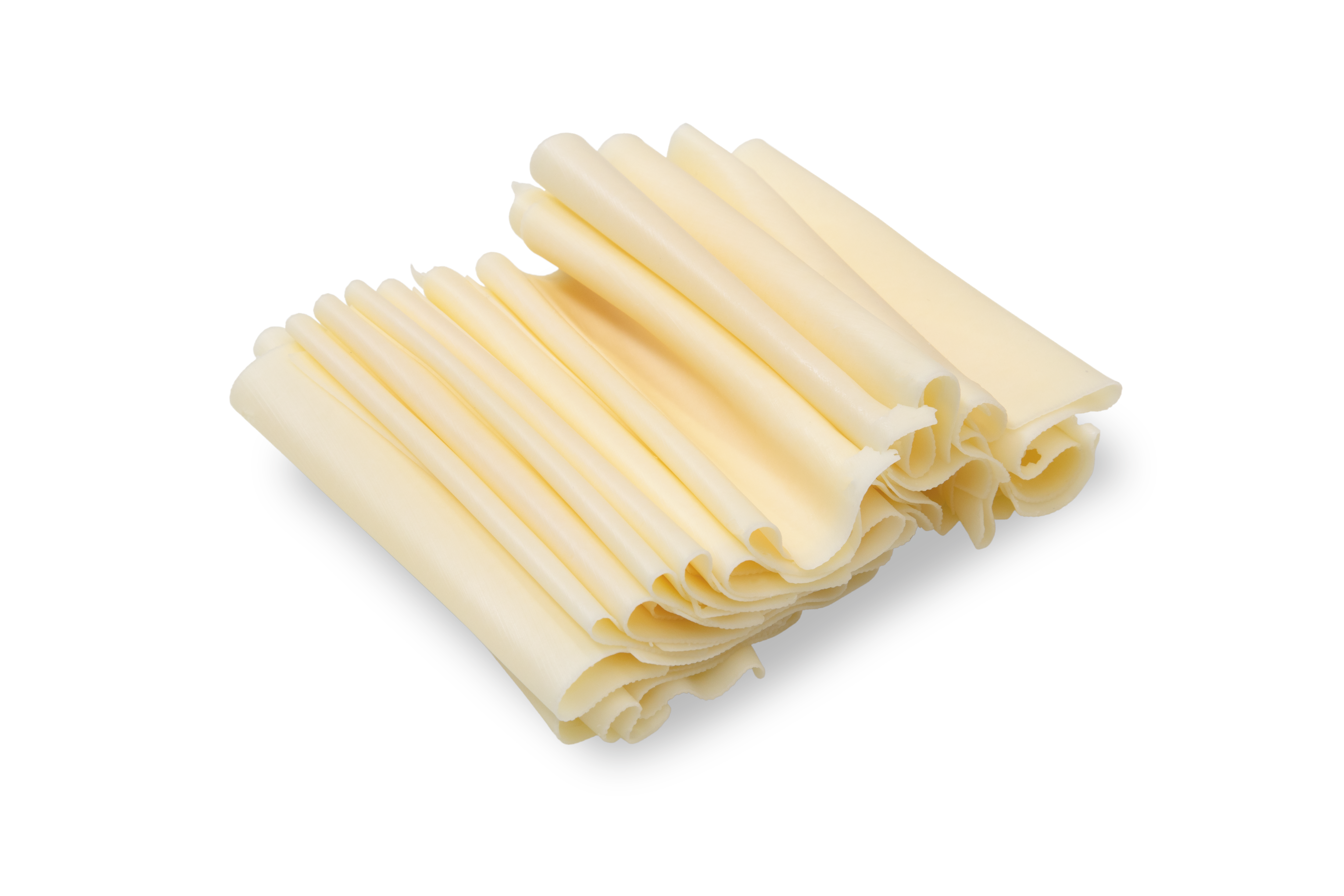

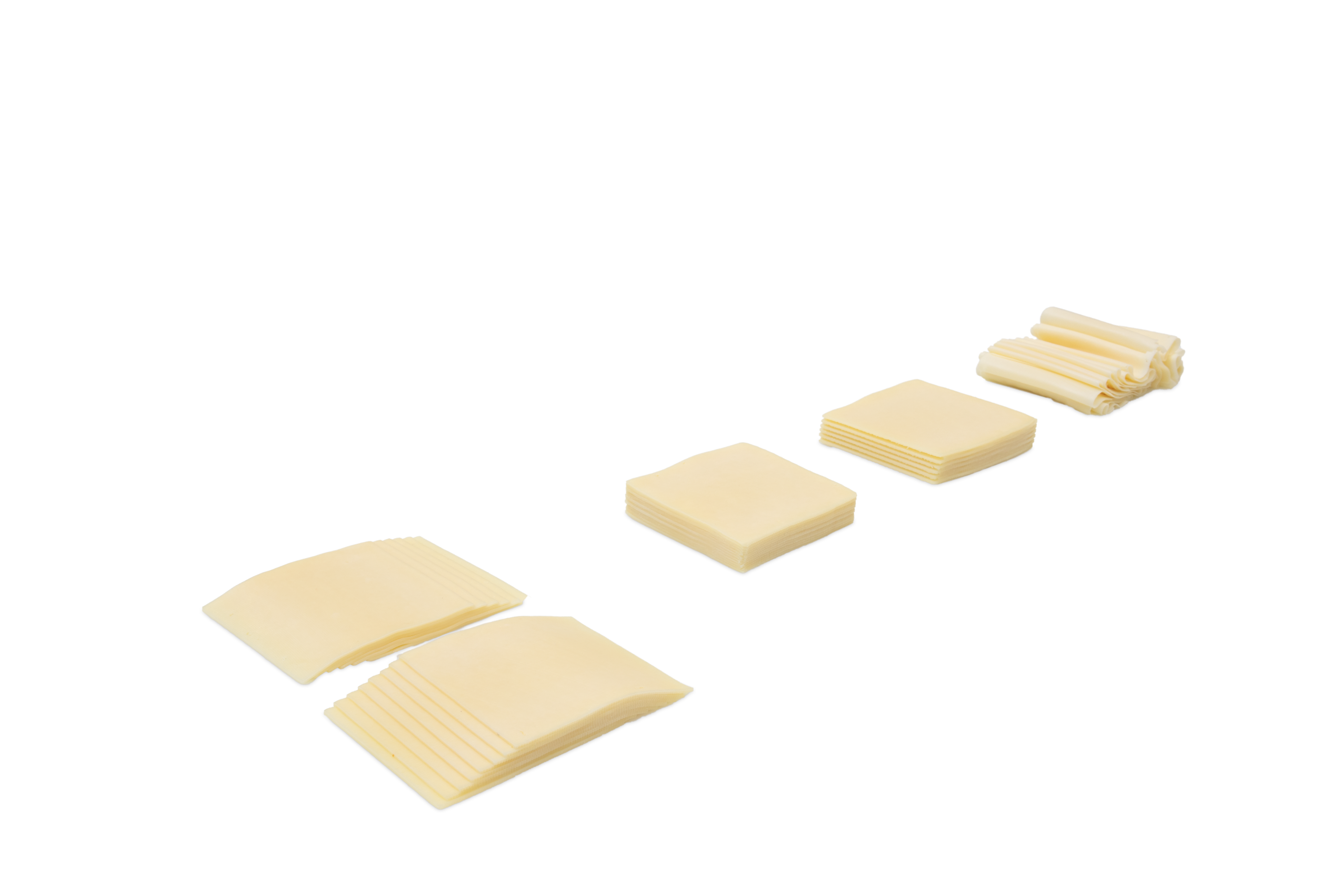

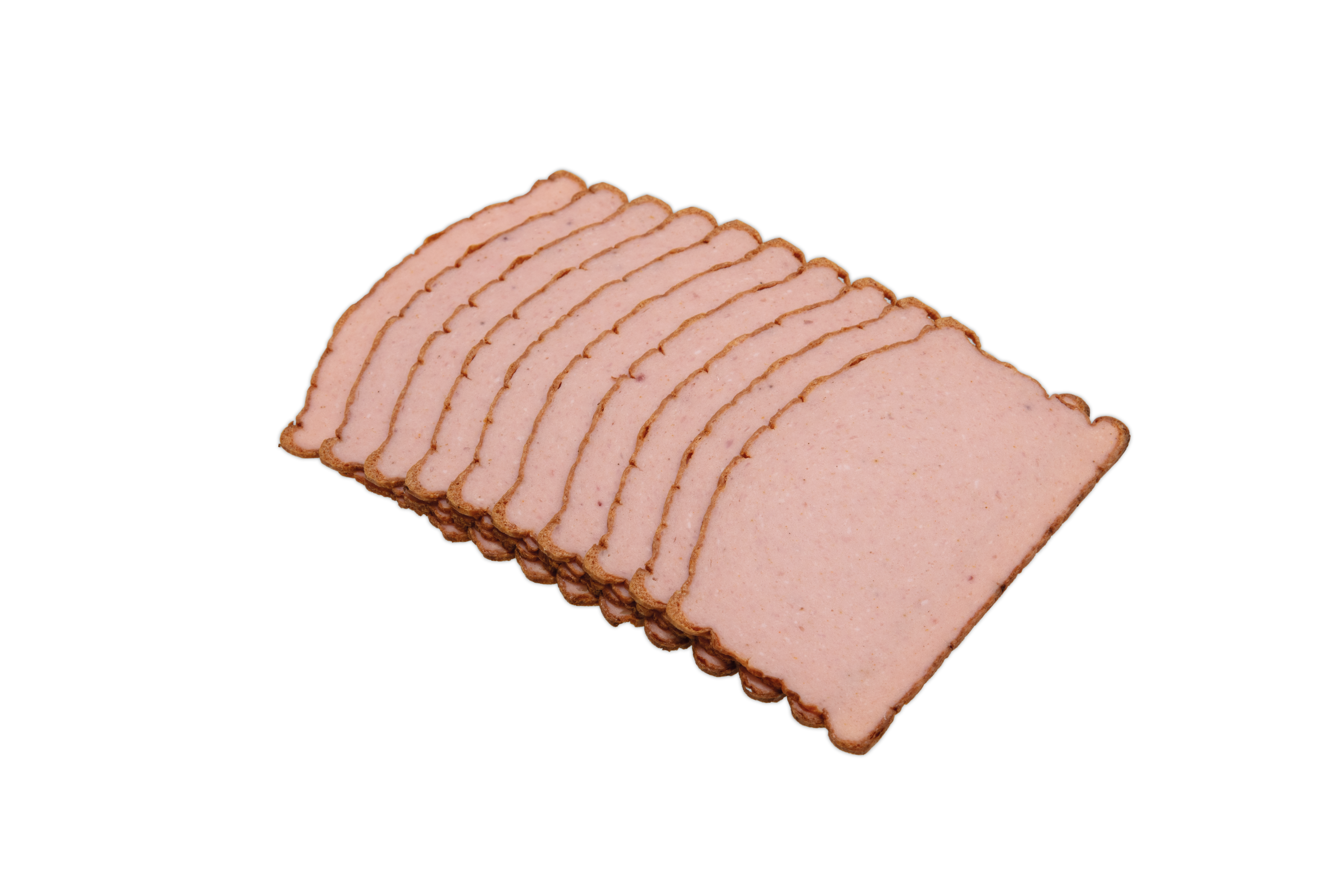

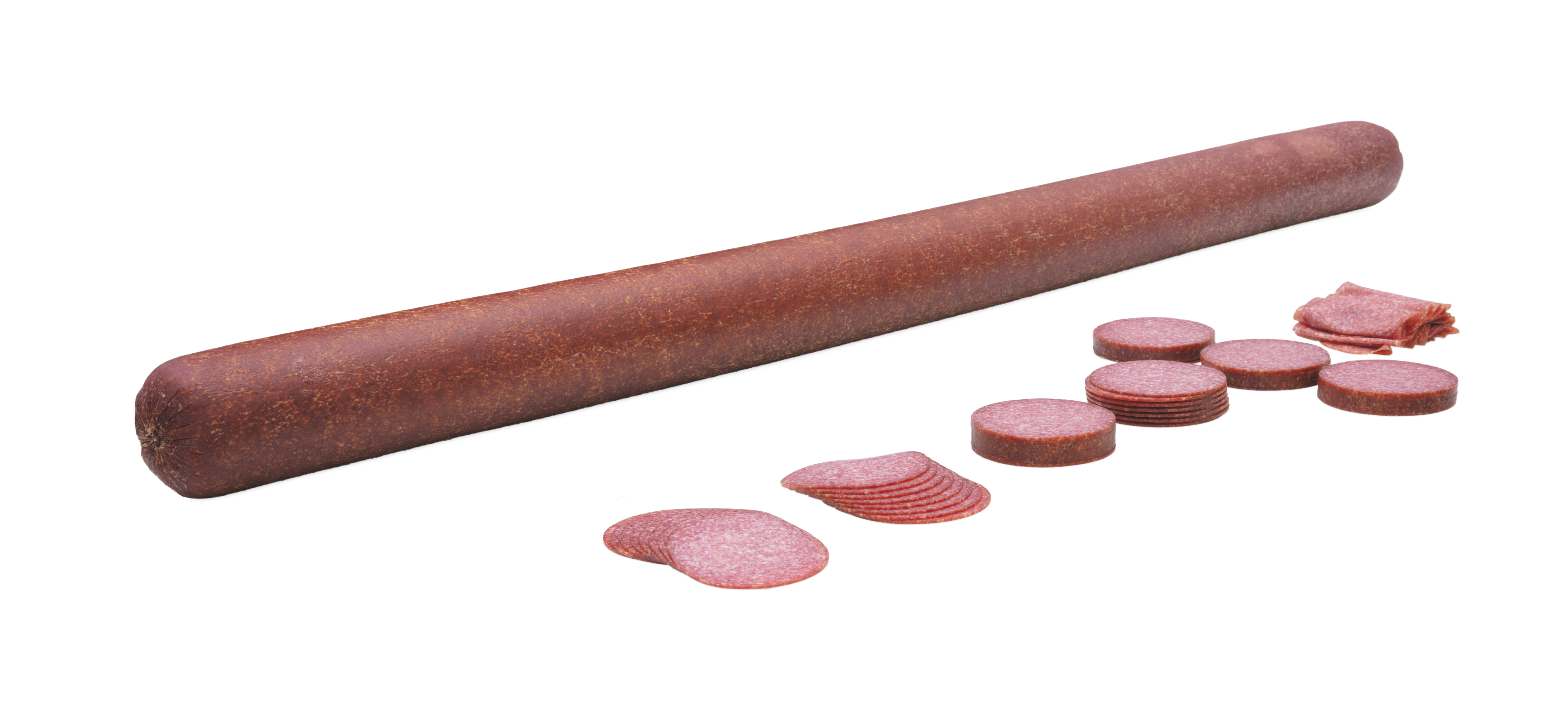

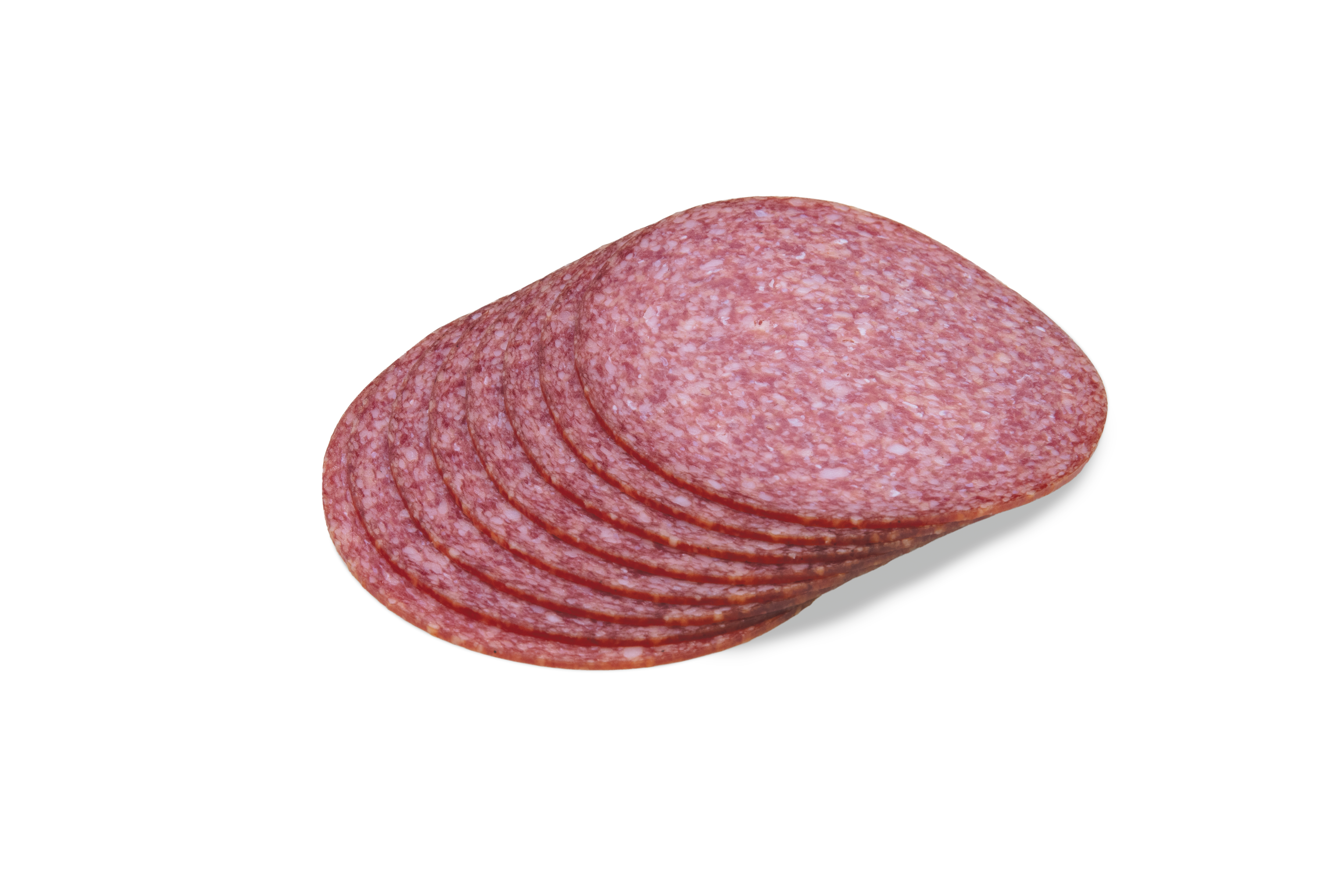

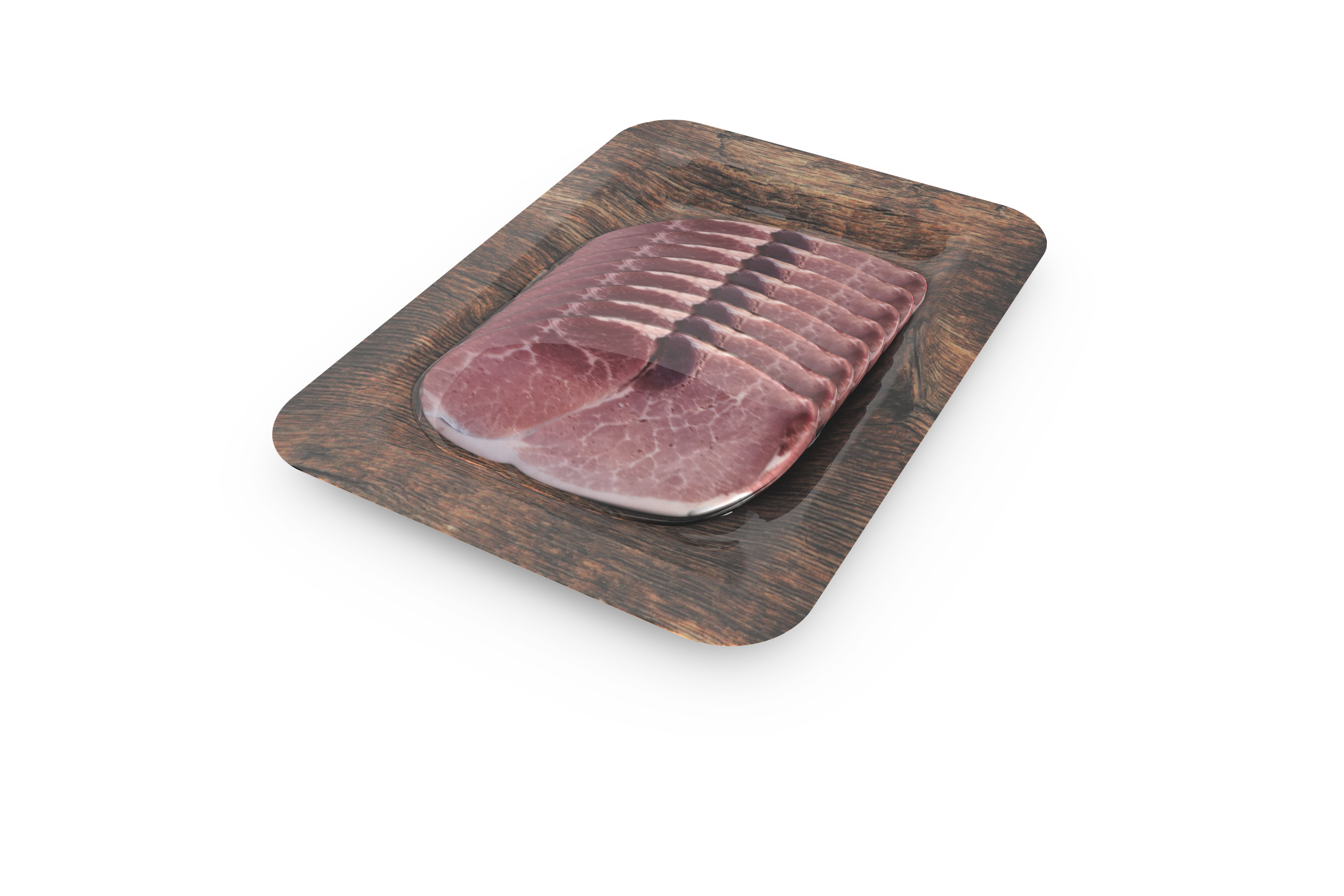

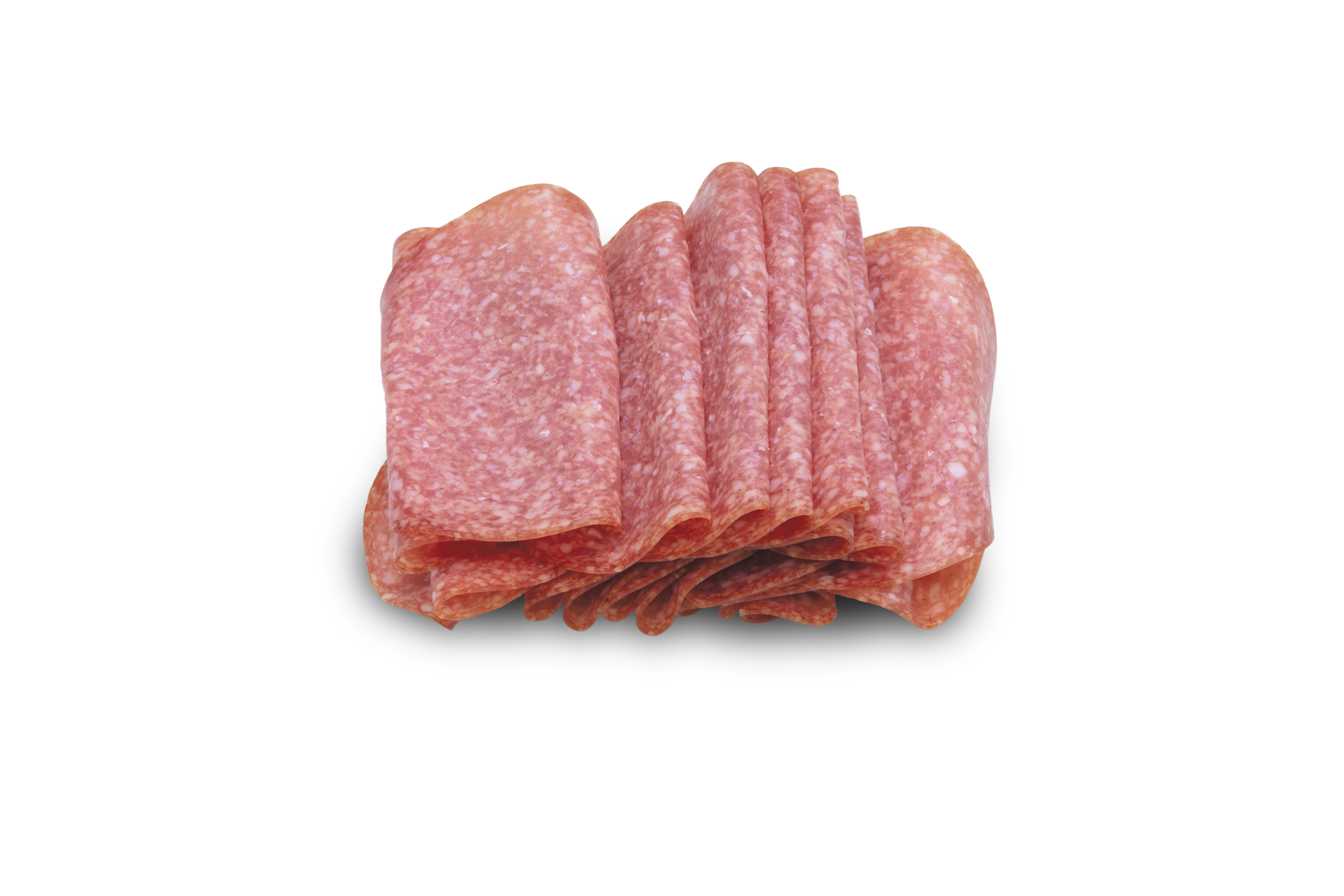

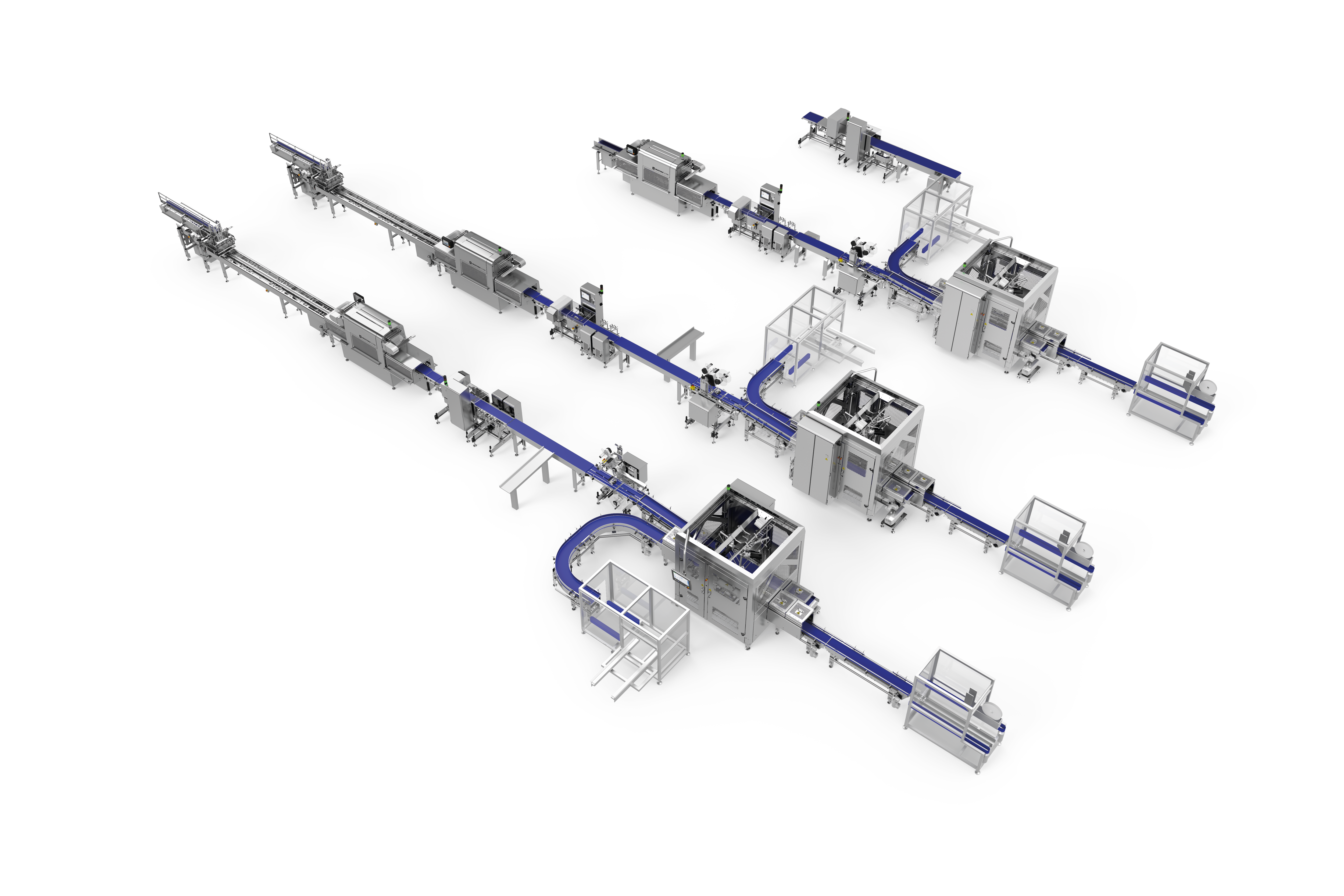

Slicing and automated packaging: Efficient line solutions from a single source

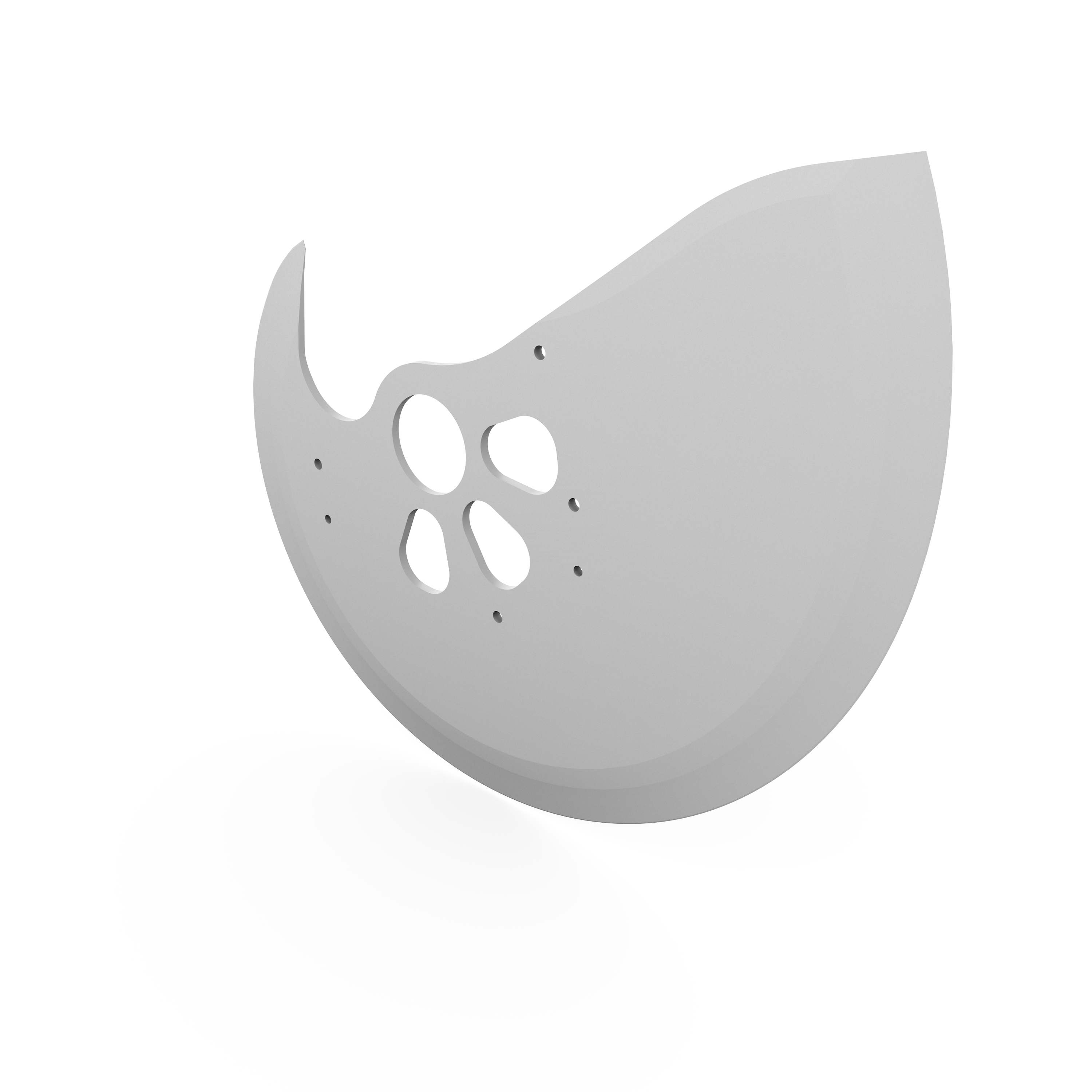

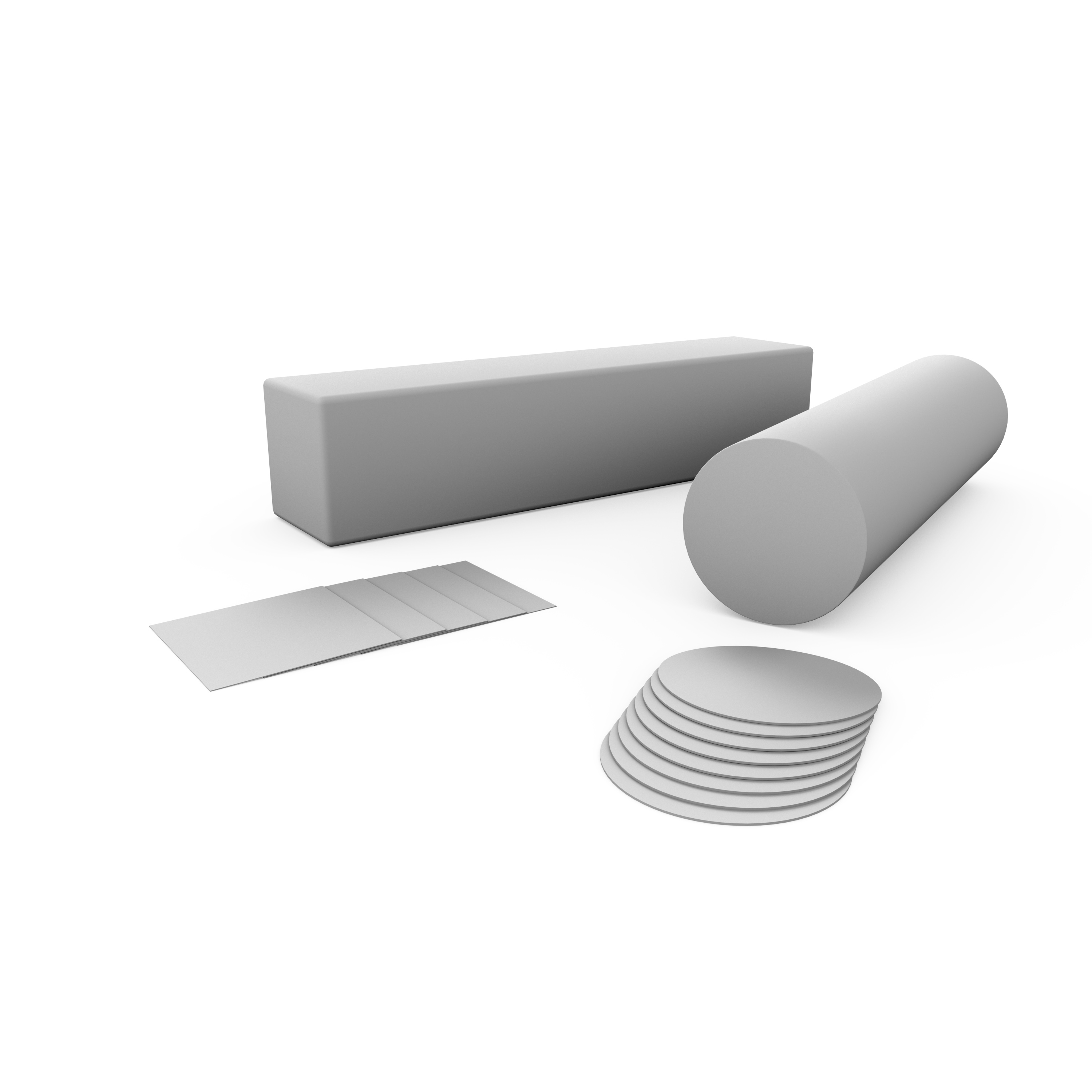

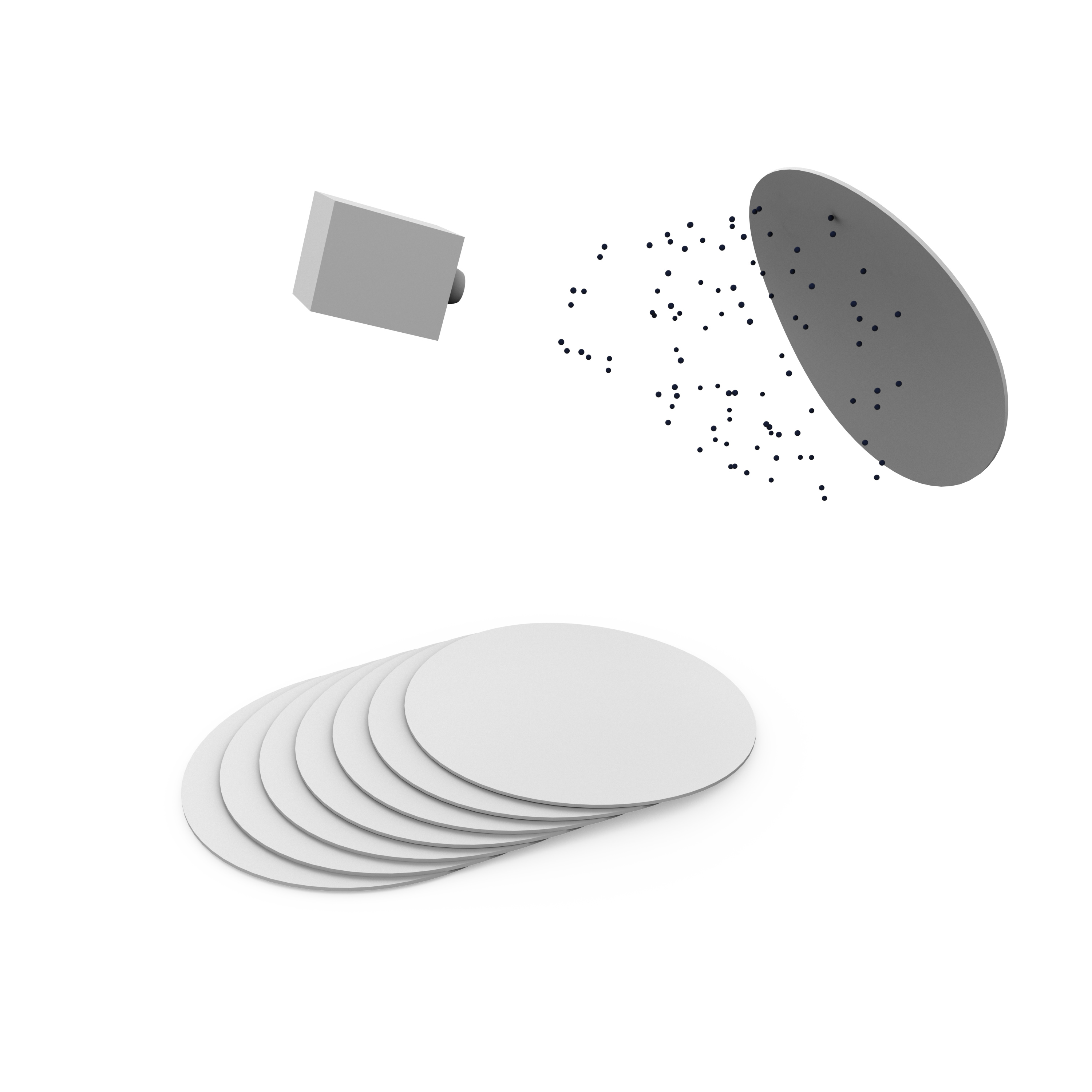

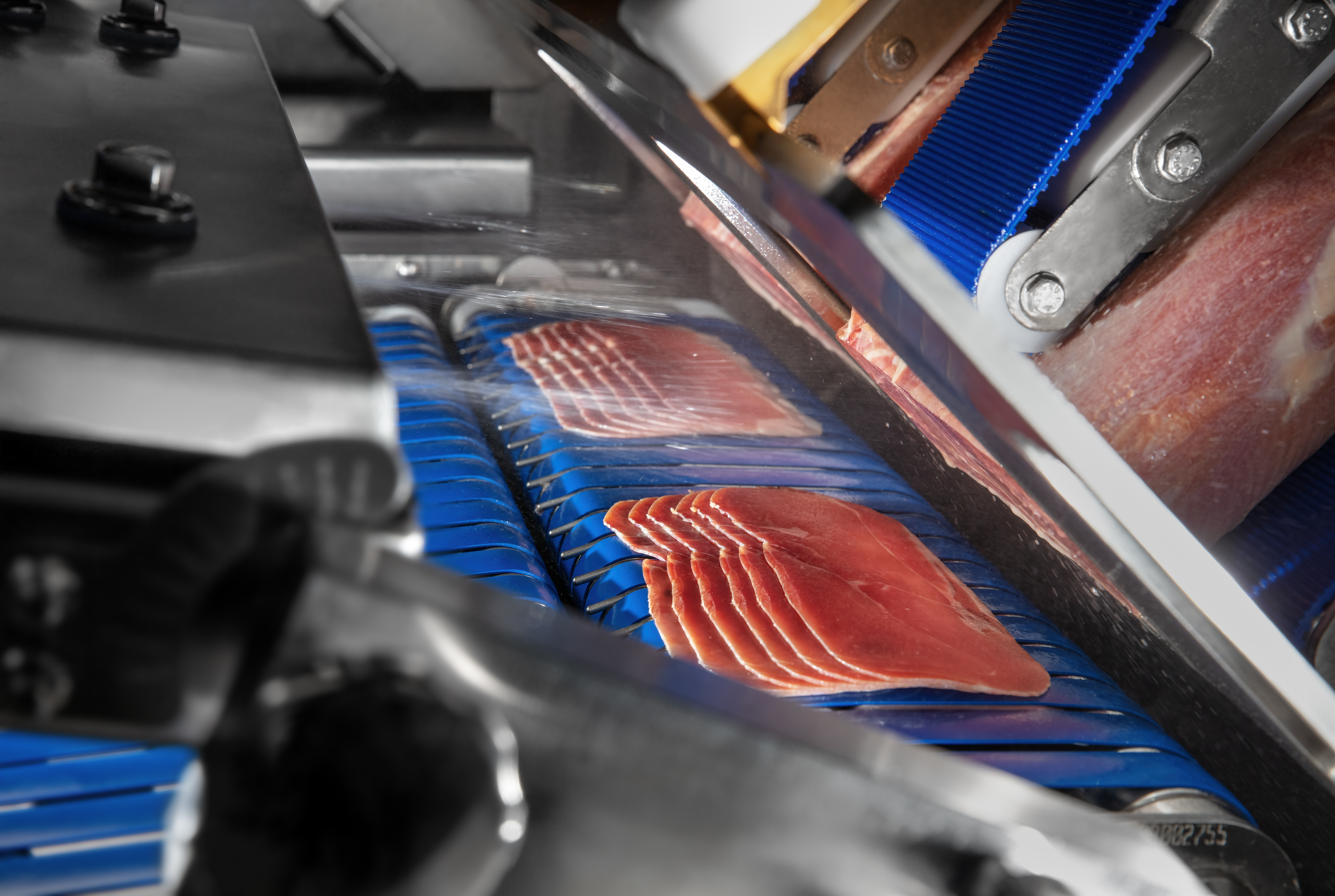

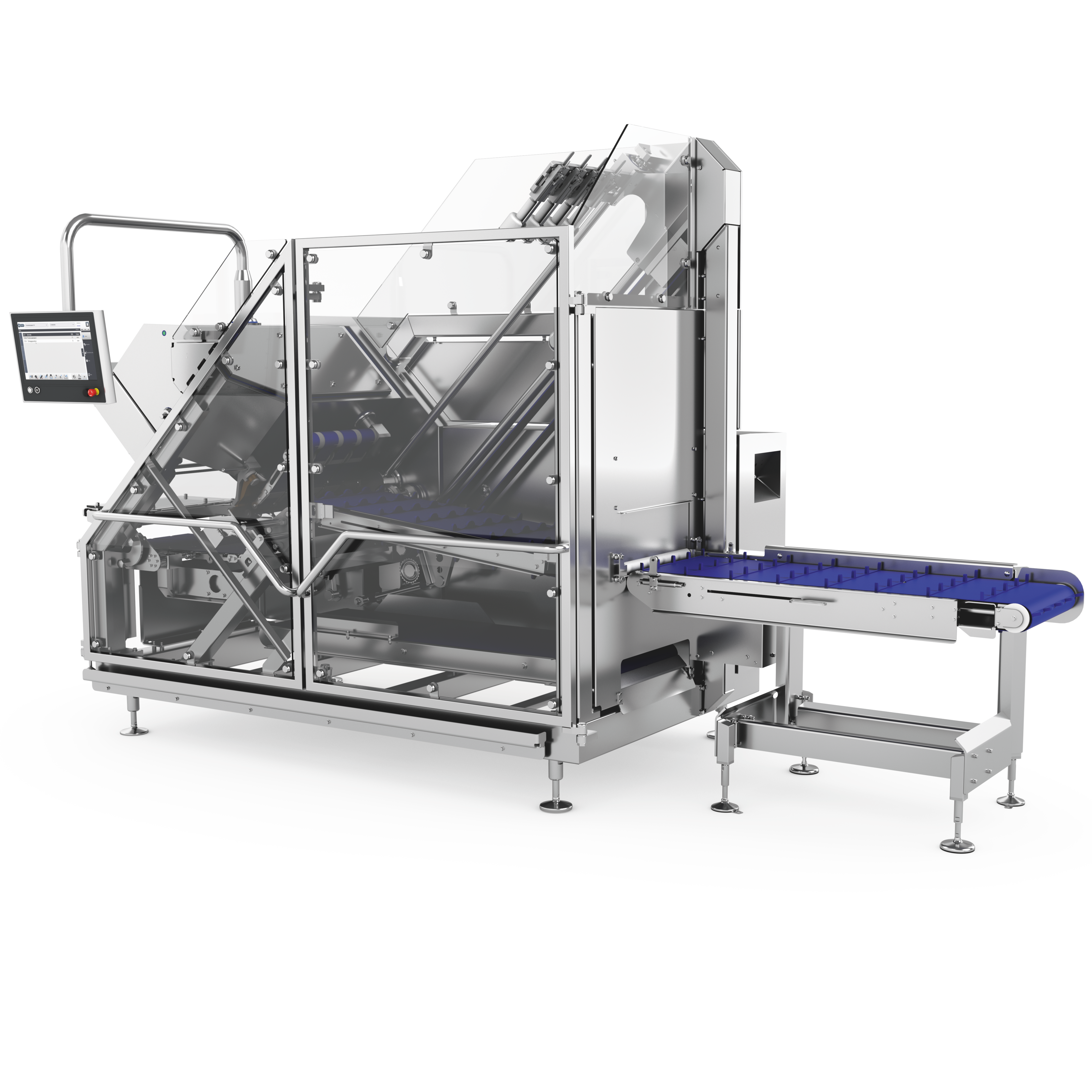

MULTIVAC slicer lines impress customers with their consistently high portion and packaging quality. Thanks to innovative slicing technology and the seamless integration of a wide variety of loading solutions, they are exceptionally high-performance, compact and user-friendly.