Ändra plats

Nuvarande plats

Looking for an impressive array of authentic and top-quality specialities? Sushi mania is not only a growing food trend, but also a renowned manufacturer with the same name of Far Eastern delicacies produced in Switzerland for the Swiss market. Products such as Nigiri, Hosomaki, Dragon Rolls and Poke stand for pure enjoyment with their special burst of freshness, and every day they delight the connoisseurs of Far Eastern cuisine in the Alpine Republic. The products, which are manufactured at the company's production site in Vuadens, are attractively packaged and can be found on the shelves of virtually all the Migros supermarkets in Switzerland, as well as being prepared within minutes and available in the so-called Sushi Corners of the 40 or so Migros branches. Now the packaging and labelling process has been raised to a new level. The philosophy: Maximum efficiency, cost-effectiveness and pack appeal - with a big plus in terms of sustainability.

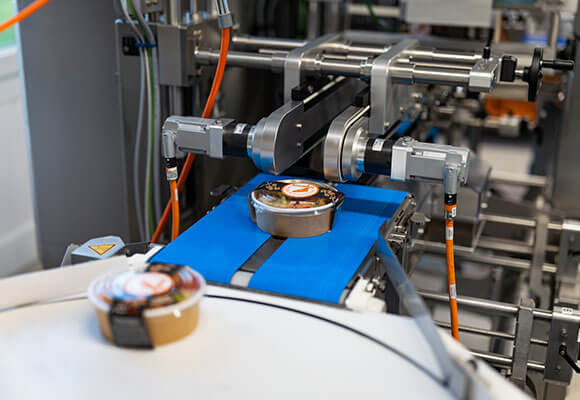

In September 2022 Sushi Mania and its 250 staff members celebrated the company's 20 year anniversary. That alone would be a good reason to take a closer look at the business in Vuadens and its wide range of products. But it is not only the sushi dishes, the spring and summer rolls, the Chirashi or Poke bowls and Edamame beans, or even the Indian, Vietnamese and Thai ready meals, which have inspired this focus on the company, but also the labelling process that reaches new heights thanks to the high-performance full wrap labeller from MULTIVAC.

Previously the fresh and crispy delicacies, which are packaged in practical round trays with a highly transparent lid, had been provided with a manually applied cardboard sleeve. The major disadvantage: The procedure was laborious, and therefore very time-consuming and costly. The stiff cardboard sleeve also largely hindered the view of the pack's content. “This is of particular relevance in the case of Asian food products,” says Marc Durst of Sushi Mania. “Because sushi products are among the healthiest and most popular food trends worldwide. The products are also extremely sensitive. The consumer wants to see (and has to see), whether the salmon, tuna, seafood, meat, vegetables, salad and rice are fresh and appetising-looking. In addition to this, the composition of the individual products or components in the pack is critical to the overall sales success. And just as important is an attractive pack design with many different functions.”

Added to this is the public recognition in recent years of the importance of sustainability, and consumer behaviour has therefore changed in this direction. The demand today is for practical packs, which are produced with a significantly lower use of materials, and which are ideally fully recyclable. But these packs must also protect the product as well as possible against premature spoilage or damage.Hinzu kommt: In den letzten Jahren hat sich die öffentliche Meinung und damit das Verbraucherverhalten in Richtung Nachhaltigkeit gewandelt. Gefragt sind heute praktische Verpackungen, die mit einem deutlich geringeren Materialeinsatz hergestellt und möglichst recyclingfähig sind. Und die dennoch – keine Frage – das Produkt bestmöglich vor vorzeitigem Verderb oder Beschädigungen schützen.

And last but not least, the aspect of cost-effectiveness was also a major consideration for Sushi Mania. The company had already come up against the limits of the cardboard sleeves. Ronald Helmel, Global Business Development at MULTIVAC Marking & Inspection: “One can automate the upstream processes, but it is still only possible unfortunately to achieve low cycle rates due to the intermittent application of the sleeves. If an additional label also has to be applied to the sleeve, as is frequently the case, we are no longer talking about an even remotely efficient labelling process, let alone a sustainable one.”

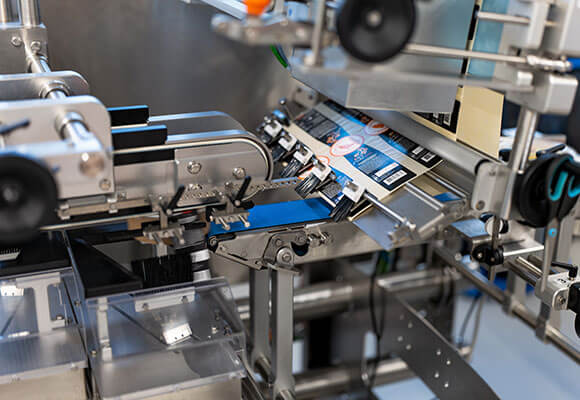

Sushi Mania had already been a faithful customer of MULTIVAC for several years, but this time the initial spark came from the MULTIVAC Marking & Inspection Roadshow - in fact just at the time, when the 3.5 ton truck from the labelling specialists was on its 12,000 kilometre tour of Germany, Austria and Switzerland, bringing full wrap labelling into focus and to the attention of Sushi Mania. The truck was equipped with a robust and high-performance L 310 Full Wrap labeller, as well as brochures, sample packs, suitable label material and state-of-the-art presentation technology.

Just like the almost 60 other customers, who were visited at their production sites in the middle of 2021, the Swiss sushi experts were visibly delighted at the benefits of this innovative labelling process. A wide range of packs can be sealed and labelled in a very sustainable way using a full wrap label, and the selection of a light label material means less transport weight throughout the entire supply chain, so that the CO2 footprint is improved from the manufacturer through to the supermarket and right up to the consumer's household. “If self-adhesive full wrap labels are used instead of cardboard sleeves, the weight of the sleeve can even be halved depending on the material used,” emphasizes Ronald Helmel. And even where the lowest-cost material is used, this packaging concept is still highly impressive with its high-quality look and feel, since the print design, shape and type of material can be individually adapted to the product and brand.

To meet the particular requirements in Vuadens, MULTIVAC developed its own label layout with perforations, so that consumers could open the bowls more easily. Adhesive-free zones in the areas of the tray side walls ensure, that the paper-based self-adhesive labels do not adhere in these areas, therefore replicating the effect of a sleeve. The label for the trays is 400 mm wide and overlaps on the base of the tray. An additional label is not required - and this also saves resources.

Just one single L 310 Full Wrap labeller is able to cope with the challenging labelling requirements at Sushi Mania. Marc Durst: “The main features of the labeller are a high degree of automation and maximum label accuracy even at high output - and this provides professional C labelling and D labelling at speeds of up to 150 packs per minute. As regards efficiency, cost-effectiveness and pack appeal, we have heralded the start of a new era.”

Thanks to the great expertise and project experience of the labelling specialists from Enger, as well as the comprehensive range of equipment options, none of the customer's wishes were left unfulfilled when it came to the individual design of the labeller: for example, the equipment at Sushi Mania was equipped with a hinged footstep to make access to the label dispenser easier. And for a particularly fast label roll change, the label dispenser is also equipped with a splice table, on which the new label strip can be easily adhered to the remainder of the depleted roll. A practiced person can perform a roll change in about half a minute.

This low-maintenance powerhouse of a labeller, which can be integrated seamlessly into new or existing lines, or alternatively used as a stand-alone solution with manual product infeed, can be designed flexibly for a wide range of packs in different shapes and materials. It therefore grows with the requirements and range of products.

In short: The new solution enables the packs to be labelled significantly faster, more accurately and more cost-effectively, and above all with greater process reliability. Ronald Helmel reinforces the point: “Thanks to the automated labelling process, producers and packers benefit greatly from the many advantages of full wrap labelling.” These include the fact, that the two staff members, who had previously carried out this tedious work at Sushi Mania, can now devote themselves to other tasks. This is a crucial aspect for Marc Durst in terms of staff satisfaction within the company, and also as regards the looming shortage of workers and skilled personnel in the sector.

03.01.2023